Post #170

Thanks for the comments Gents; Mark your car is looking good!

Had a full day on the car today. Been collecting a few bits and bobs too, and getting a few jobs done.

I had hoped today would be putting the rack on the subframe now I've got the AN fittings done (and also the longer GTI6 track rod arms on in place of the VTS ones) but when I saw the weather this morning I thought better of lying on my back in a puddle.

So I put the EZ up, up, and weathered the storm. Decided to focus on the new rad I've bought and look at fitment, oil cooler, fan etc and also take a look at the high pressure PAS hose from pump to rack.

This was where I started.

So old rad out, oil cooler out (doing an oil change anyway), and offered up the new rad. Just an eBay special 205GTI alloy job. The passenger side foot sits in an existing hole just inside the original, so that's an easy swap. Then line up and drill and new hole for the driver's side foot.

Then I looked at the mounting on the top of the rad. Obviously the slam panel is being cut out for the maxi airbox (hence the lower rad in the first place), so I will mount the rad at the side of the front cross member legs using a rubber bobbin.

Here on the driver's side I'm measuring up the gap from side tank of the rad to the bobbin, and I'll ask the alloy welder I know to make some brackets on each side of the rad to fit to the bobbin.

Also on the rad, both the inlet at the top and outlet down the bottom are 32mm. My hoses are 38mm Spoox jobs, so I need to make the two meet. I'd also quite like to get rid of the 90 deg bend in the inlet, and just have it straight to the hose. I looked into some other bits and bobs I had lying around to see if it would fit, and hose joiners etc but if I can weld on an alloy 38-32mm reducer to each outlet then all I need is to join my existing hoses up. Car builder solutions do them, so that looks like the best bet if the alloy is sufficiently good to weld.

So at this point I was offering up the new 10" Spal fan, etc to see how it would all fit. I chopped the slam panel, and just happened to find a nearly new 19 row Mocal oil cooler in a box of bits in the garage as you do, so my old 16row cooler is now redundant. This was an initial look;

Basically happy with that, but proceeded to try all sorts of cooler positions looking at the combo of hose access to the sandwich plate along with bracket options. It's just a little too tall to mount as I would like (like the old one), but instead of going upside down like the pic, I'll probably keep it the right way up, and I think some brackets of the front cross member will do fine.

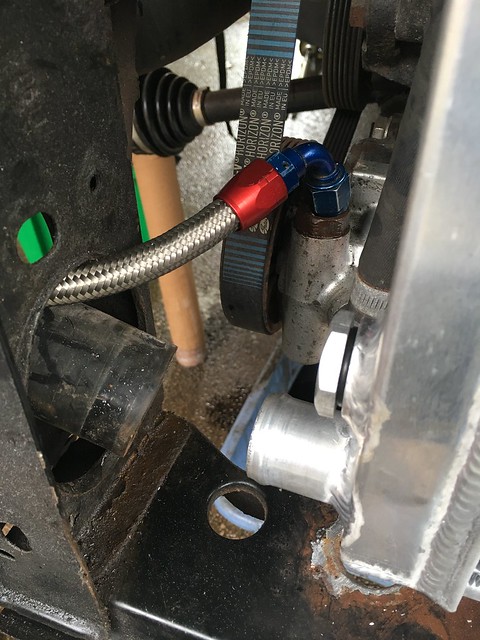

So now turned my attention to the PAS hose. It always irked me how long a run the OEM hose takes under the sump etc etc, so with it being relocated anyway, I wanted to look into a doing a short run under the drivers side chassis rail like the coolant hose.

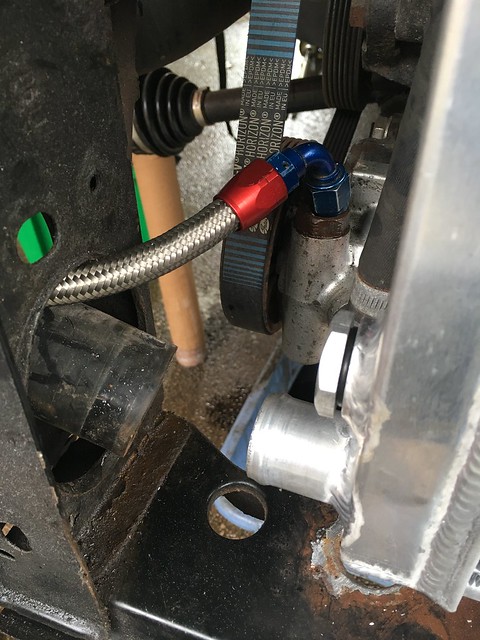

First up undid the hose and looked to see how it would bend away from the alternator belt and see if it could follow my intended path.

It looks do-able using this hose; although I would make it's own hole in the cross member leg by enlarging the existing one just above the coolant hose hole.

I then had a look if -6 would bend..

Obviously it's just offered up but I think it will do. What I'll do next is investigate if a company like Pirtek could make something with a longer custom (steel) bend in it, that would bend round tighter before joining to a hose before making it's way back to the rack.

I think I can get the rad brackets and outlets done this week, but getting the hose done is less likely.

Inevitably as the cross member and the driver's side inner arch panel are the only ones I haven't tackled yet during the project, now's the time to do a bit of de-rusting so in my last hour tonight I did a bit of sanding, (the spot welds in particular) and did some liberal de-rusting using the Bilt Hamber product again to leave it to pick up next time, with primer and paint then as the rad and hoses come together I should have everything ready.

The only missing part of the jigsaw is header tank and filler hose. I'll probably get a universal alloy job. It took me a while to figure out how folk that do the 306 - 205 conversions tackle the filling from the header tank. I have seen since that Spoox even do a specific heater matrix hose with an integrated filler hose teed into it, but having seen it, I should be able to just get an alloy T piece and splice it in, and the header tank can be mounted nice and high on the bulkhead..

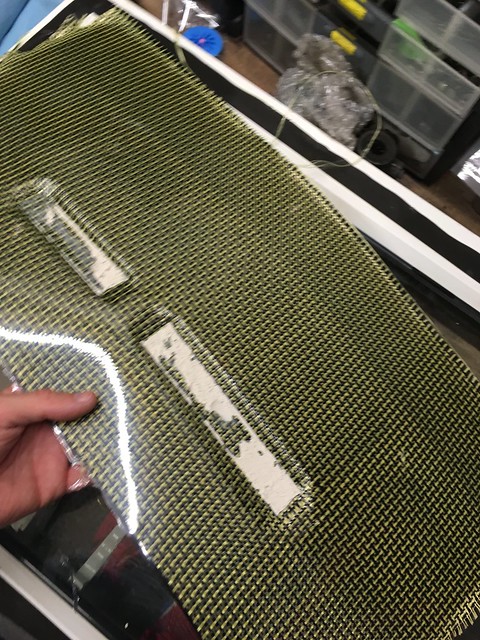

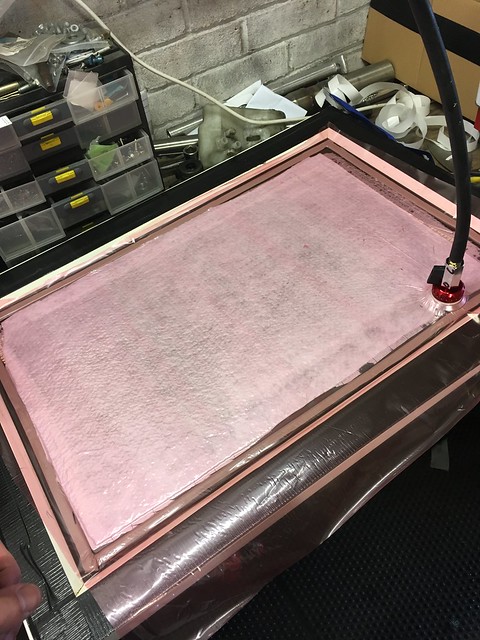

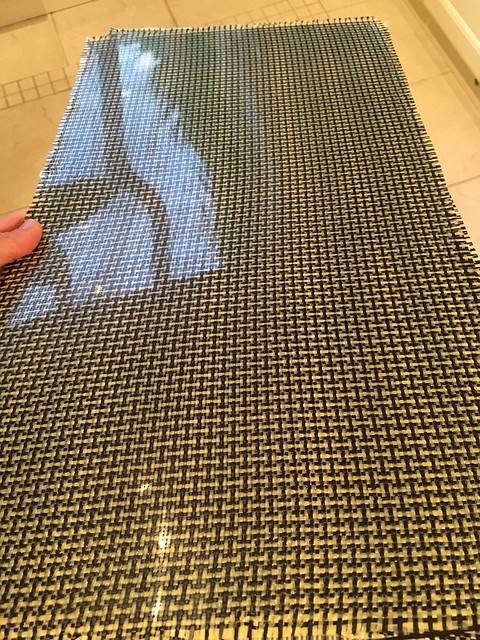

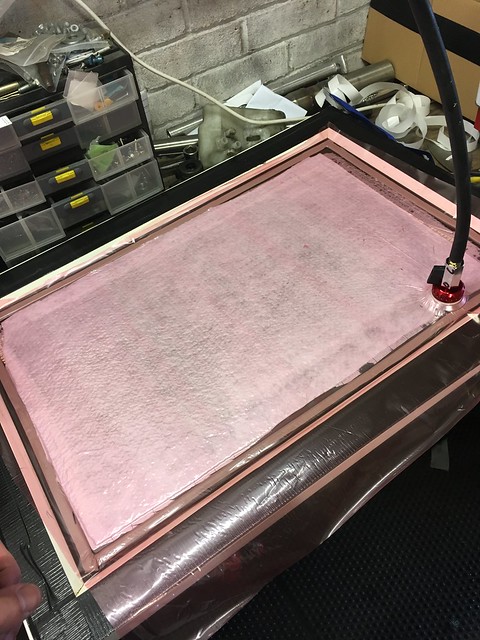

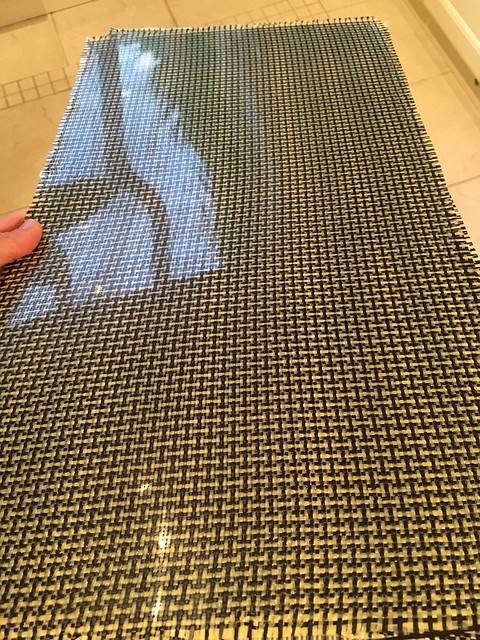

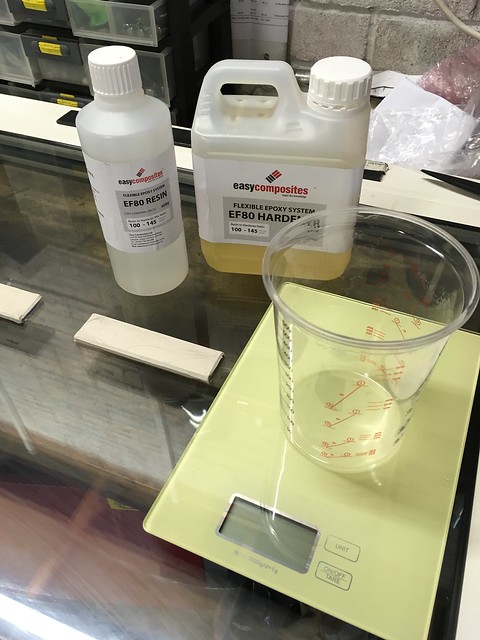

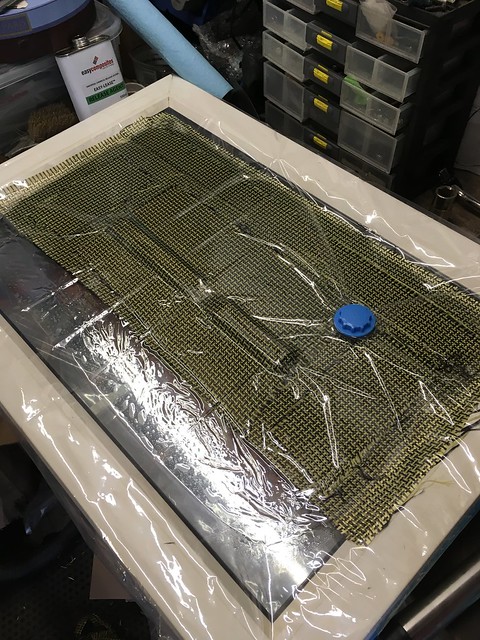

Think that's about it for now. Got a new oil catch tank from Ralloy, but not looked at fitting it yet, and also had another play with laying up some carbon kevlar for rear stone guards in the inner wings. Went the whole hog this time with peel ply, absorbant layer and vac bag with valve etc. Turned out really well, was well chuffed..

cheers

Iain

jonbb

jonbb

[/url]

[/url]

[/url]

[/url]

[/url]

[/url]