Post #113

I've not got there yet mate. Am procrastinating to say the least.. One place was basically a tenner a side, another £50.. Decided today I'd plump for the original Dimma top mounts only to find they're NLA, so unless anyone has any spare they'll sell me I'm back round to the turret top re-enforcement again.

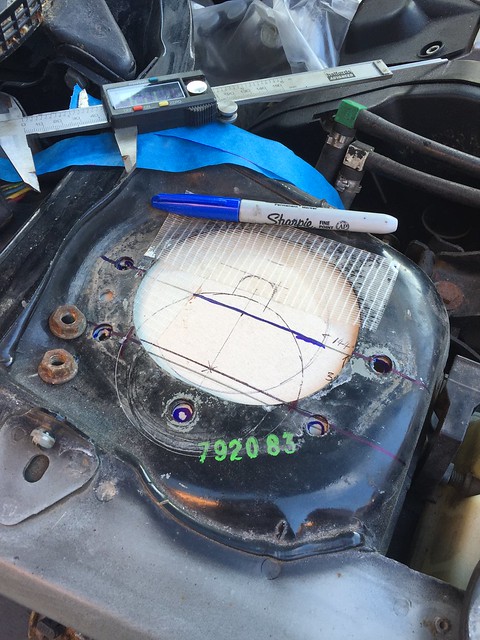

The problem is Damien that I pretty much sorted a template from 3mm steel that I wanted to have laser cut in 5mm steel, but it then struck me being a bit daft to do that then use the OEM mount underneath. However not being a race car, I didn't want to do the whole solid mount bearing thing. (Been there before) hence my to-ing and fro-ing.

I think 3mm welded underneath the turret top would probably be sufficient and I could do that myself to use an OEM top mount so I might end up there as well..

Ok on to other things, what's been going on I hear you cry..?

I've revisited the rear qtr panels again, attempting to improve further the finish before painting. Having passed them each day back and forth walking past the car allowed me to spot little areas I felt I could improve, so on the back end of the decent weather the other week (remember that; the Summer of '17) I cracked on with a bit more bodywork.

So up went the EZ up again, lots of rubbing down, Dolphin Glaze, filler primer, and final primer ensued..

(Forgive the two-tone primer effect!)

Anyway, pretty darn pleased with how that turned out, you'll have to trust me I haven't re-posted the pics from a few pages back!

In the meantime I gave my Bilsteins a lick of paint.. turned out well.

I also scored some brand new AP rotors 330x28mm exact same spec as I needed for basically half price

Somewhere down the line I sourced an ATL filler for a bargain price then found an equally bargain-ous matching fuel neck - just need to re-drill the bolt holes. (Dave - Car builder solutions #FN2 if you're interested!)

Also stumbled upon a little used steering wheel - this is a fraction smaller than my current one, and a bit deeper. The net effect is that I now have more clearance between the bottom of the wheel and the sides of my seat, so I can get into my seat easier and have a better position as well.

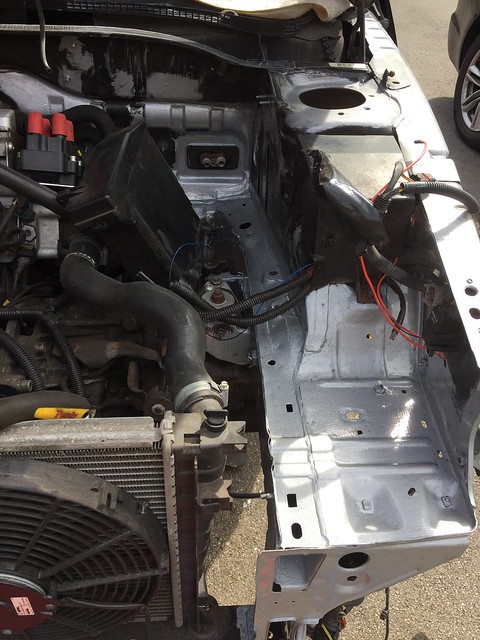

Next up, thought I'd tackle the remaining inner arch, the OSF. Out came the grinder and oops, found some rust which became a hole..Cut it right back to do a repair. Oddly this little bit was far worse than any other bit; the rest of the inner arch was pretty good. Thought I might find more lurking under the stone chip but thankfully not.

Patch being sized up..

And home..

Proper anti-rust treatment and paint etc to come. May be tomorrow if the weather is kind..

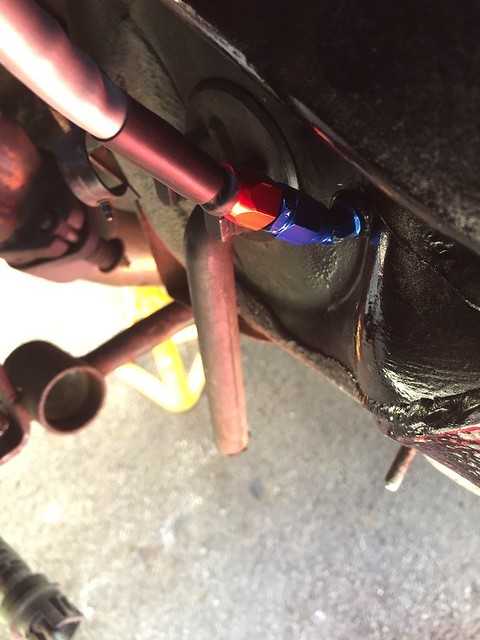

Now then, what do we think of this little fellow? Wasn't expecting it to come with the bronze bush which was a bonus (pic showed plastic one), but the ball end of the lever looks a fraction longer than the one that came off it.

What do you think? Will it be ok?

That's about all from me right now. Chasing up parts and jobs still.. becomes a bit of a weekly chore, but hopefully getting there. Poor Andy has had most of my beam ready to go for ages, and we're waiting on a part which will hopefully come soon so the beam will be completed.

I also bought all my paint last week, so slowly but surely getting there..

Thanks for all your contributions and positive comments guys, keeps me going!

Cheers

Iain

RallyeRed

RallyeRed