________________________________________

1990 205 gti6 supercharged

|

| Author | Subject: Goldie the track car |

stef306 stef306

Regular Location: lyme regis Registered: 20 Sep 2009 Posts: 201 Status: Offline |

Post #626

dont feel bad steve your on par with me now ive had 3 chargers  ________________________________________ 1990 205 gti6 supercharged |

|

|

|

prism7guy prism7guy

Seasoned Pro Location: DoncastAAAAARGH Registered: 13 Jan 2008 Posts: 4,640 Status: Offline |

Post #627

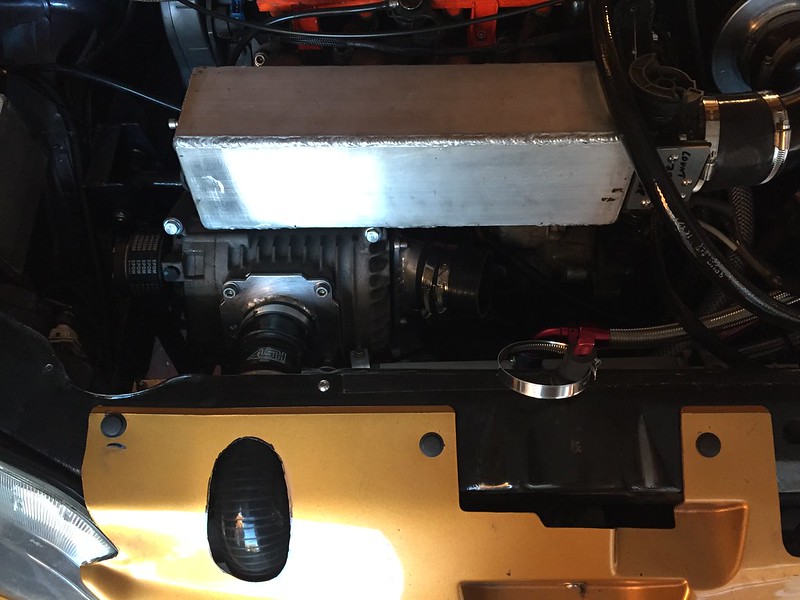

I'll race you to the 4th charger then Stef  I've fitted charger #3, belt back on and most of the pipework back in place. I'm getting pretty fast at changing them now.    IMG_5765 by Steve Count, on Flickr IMG_5765 by Steve Count, on FlickrHad a phone call today, i should expect delivery of the new dump valve on monday, i've bought an ally hose joiner to butcher and weld the tial flange to, just hope it fits in the limited space that i've got. Also got some newer R888's fitted today ready for Blyton next Saturday, hopefully everything comes together in time as i've still got to fit and bleed some 6 pots for a mate before that day too  ________________________________________ Goldie the track car. |

|

|

|

prism7guy prism7guy

Seasoned Pro Location: DoncastAAAAARGH Registered: 13 Jan 2008 Posts: 4,640 Status: Offline |

Post #628

Well, time for another small update, things aren't going as planned for me at the moment   My new dump valve has arrived, but fitted with the wrong spring. (Came with a -10psi fitted, i ordered -2psi for s/c applications). Called up the supplier and they said they'd get back to me but never did, hopefully i'll get hold of them tomorrow and they will have the correct spring in stock and get it sent to me by friday or its going to be one crap trackday. Regardless of this issue i've carried on with getting everything else fitted, so here are a few pictures.   IMG_5781 by Steve Count, on Flickr IMG_5781 by Steve Count, on Flickr IMG_5782 by Steve Count, on Flickr IMG_5782 by Steve Count, on Flickr IMG_5783 by Steve Count, on Flickr IMG_5783 by Steve Count, on Flickr IMG_5788 by Steve Count, on Flickr IMG_5788 by Steve Count, on Flickr IMG_5785 by Steve Count, on Flickr IMG_5785 by Steve Count, on FlickrThe only place i could squeeze it in  And for anyone that likes a little whine, i got a video the other day before the boost pipework was done up. clicky ________________________________________ Goldie the track car. |

|

|

|

Chr1sch Chr1sch

Seasoned Pro Location: Worcester Registered: 02 Aug 2014 Posts: 1,025 Status: Offline |

Post #629

Wow that is Whiney! I had a modified cooper s and it was nowhere near as noisy -love it!(if it's healthy...) |

|

|

|

demondriverdan demondriverdan

Seasoned Pro Location: Londinium Registered: 29 Nov 2010 Posts: 2,665 Status: Offline |

Post #630

Was just watching your Nordschleife video, what's stuck to the bottom of the windscreen?________________________________________ Rallye Race Car |

|

|

|

stef306 stef306

Regular Location: lyme regis Registered: 20 Sep 2009 Posts: 201 Status: Offline |

Post #631

glad you got one steve shame they messed you about on springs. I did warn you there massive! and i thought the 6mm vacuum line was ott haha. Should transform the throttle and running of the car now. ________________________________________ 1990 205 gti6 supercharged |

|

|

|

prism7guy prism7guy

Seasoned Pro Location: DoncastAAAAARGH Registered: 13 Jan 2008 Posts: 4,640 Status: Offline |

Post #632

The whine sounds a bit louder in that video than in the flesh, hopefully this charger is healthy as i cant afford to go buying a fourth one as a replacement!  It might also be loud because in that video the inlet to the charger goes straight to the air filter, no throttle body in place to quieten it down, and likewise, the outlet just goes through the intercooler and vents to atmosphere, not the engine. I'm guessing you mean the Nordschleife videos from 2013 Dan? If so the bottom right on the windscreen is a suction mounted phone holder, made life easier using the phone mounted there to control the go pro. To the left of the windscreen is the tax disc holder, but i guess i can remove that now and save a few grams  I've been in touch with them today Stef, correct spring should be with me tomorrow  With any luck i'll not have any more issues with the car anymore. With any luck i'll not have any more issues with the car anymore.How much boost are you running with yours? Mind me asking what pulley sizes you run aswell? Just wanting to try and figure out how much air yours will be blowing through the valve at say 7000rpm with the throttle closed, you're now running an M90 arent you? ________________________________________ Goldie the track car. |

|

|

|

Day666 Day666

Seasoned Pro Location: Bristol Registered: 20 Apr 2013 Posts: 5,214 Status: Offline |

Post #633

Can't wait to see this finished..make sure you keep posting pics ...good luck that the spring coming sorts things  |

|

|

|

stef306 stef306

Regular Location: lyme regis Registered: 20 Sep 2009 Posts: 201 Status: Offline |

Post #634

Im running a soild 0.8 bar pretty much there from the word go now about .6 at 2k id say. I run a stock c/p 127mm and a stock 3" s/c pulley im spinning mine extremely slow it was this or no boost we tried a 90mm c/p and i made nothing lol. im on a m90 gen 3 but with the later case porting dont ask the difference in performance as im not sure. The m90 flows 1,400cc and the m62 flows 1,000cc but thats based on the gm m62 which has near the same rotor pack as the m90. The merc m62 is a bit of a funny one as it shares the same rotor pack as the m45 nearly its going to be a hard one to judge. Ive a boost calculator here if you want it just message me on faceache and ill send it you. As for filters im now only using a cone and a trumpet sock as it was creating vacuum on the charger could have been the cheap filter i was using. ________________________________________ 1990 205 gti6 supercharged |

|

|

|

prism7guy prism7guy

Seasoned Pro Location: DoncastAAAAARGH Registered: 13 Jan 2008 Posts: 4,640 Status: Offline |

Post #635

Just tried doing a few calculations for theoretical flow rates.Mine: Crank pulley = 128mm S/C pulley = 80mm 128/80=1.6 = Pulley ratio S/C displacement per rev = 1.016Litre 7000(rpm)*1.6=11200rpm for s/c at 7000rpm crank 11200*1.016=11379.2 Litres of air per min 11379.2/60 = 189.65 Litres per second. Yours: Crank pulley = 127mm S/C pulley = 76.2mm 127/76.2=1.667 Pulley ratio S/C displacement per rev = 1.475Litre 7000(rpm)*1.667=11669rpm for s/c at 7000rpm crank 11669*1.475=17211.775Litres per min 17211.775/60=286.86 Litres per second. Mine should be flowing around 66% of the air that yours is if my calculations are right, which means the Tial should be more than up to the job of mine if it handles yours with no issues.  I wish i knew why my boost peaked at 6psi by 3000rpm then slowly dropped down to 4psi, i was under the impression it should stay fairly stable or rise a little with revs. Two theories of mine are the charger heats the air up making it 'thin' and not compressing it enough, or somewhere in my inlet system is a bit restrictive causing an issue with the amount of airflow needed to maintain a decent boost pressure at higher flow rates, i know the two 135 degree elbows between the intercooler and manifold won't help flow rates, so eventually i plan on making a much nicer run between them, hopefully much more laminar airflow. ________________________________________ Goldie the track car. |

|

|

|

stef306 stef306

Regular Location: lyme regis Registered: 20 Sep 2009 Posts: 201 Status: Offline |

Post #636

the tial valve is rated upto "1800bhp"  i dont get any inlet gargle so you will be ok. Silly question youve checked for boost leaks and your cam timing ? i dont get any inlet gargle so you will be ok. Silly question youve checked for boost leaks and your cam timing ? ________________________________________ 1990 205 gti6 supercharged |

|

|

|

phillipm phillipm

Seasoned Pro Location: Rotherham Registered: 15 Oct 2006 Posts: 20,607 Status: Offline |

Post #637

Some of it would be the heat buildup against the second body - with enough boost there to choke the charger it must have been doing some fair work.________________________________________ - Bespoke rollcages/additions/adjustments. Half cages right up to complete custom spaceframes - MSA/FIA spec, CDS, ROPT, T45, etc - PM meEmail me! Custom-made polybushes available - need an odd size or fitment? - anything from batch work to one-off pieces. |

|

|

|

prism7guy prism7guy

Seasoned Pro Location: DoncastAAAAARGH Registered: 13 Jan 2008 Posts: 4,640 Status: Offline |

Post #638

Last time I checked the cams were timed to standard settings (drill blanks fitted in fine when locked up).I haven't checked for boost leaks to be honest, but if it's making 6psi low down surely any leaks would mean that it stayed at 6psi rather than Peter off with revs?  I reckon a lot of it would be to do with the heat as the charger was getting way too hot to touch by hand, when I had this new one running the other day it stayed cool for the few minutes it was running, the previous ones would be quite hot after just a couple of minutes. What's the best way to check for boost leaks? It's been a long day  When I was checking my manifold for leaks I just kept spraying it with carb cleaner with the engine running and you could hear the engine note change when I sprayed it at a leak (the manifold warped a bit with the welding where it met the head, so i just kept nipping up the bolts a little more to seal it against the ptfe gasket). ________________________________________ Goldie the track car. |

|

|

|

phillipm phillipm

Seasoned Pro Location: Rotherham Registered: 15 Oct 2006 Posts: 20,607 Status: Offline |

Post #639

Works well enough, you used to be able to get little smoke bombs you could pop in the intake at motorfactors but I haven't seen any for years, maybe ebay?________________________________________ - Bespoke rollcages/additions/adjustments. Half cages right up to complete custom spaceframes - MSA/FIA spec, CDS, ROPT, T45, etc - PM meEmail me! Custom-made polybushes available - need an odd size or fitment? - anything from batch work to one-off pieces. |

|

|

|

stef306 stef306

Regular Location: lyme regis Registered: 20 Sep 2009 Posts: 201 Status: Offline |

|

|

|

|

prism7guy prism7guy

Seasoned Pro Location: DoncastAAAAARGH Registered: 13 Jan 2008 Posts: 4,640 Status: Offline |

Post #641

Time for a small update i guess.I made it to the trackday at Blyton park without any issues, it stayed dry all day which was a bonus.  IMG_5798 by Steve Count, on Flickr IMG_5798 by Steve Count, on FlickrThe car ran pretty faultlessly all day, the only issues i have is keeping the oil and coolant at sensible temperatures, the oil will get to 130c pretty quickly and the coolant to around 100-105c. I cant really get the temperatures down whilst out on track even when i slow right down, but as soon as i pull off into the pits and leave it ticking over for 5 mins they very quickly stabilise around 90c, so it's not a fan issue, just the shear amount of heat that the poor radiator is trying to get rid of. I think it might be time to consider fabricating my own and shuffling some stuff around to get it to fit, or have a custom one made. Both options will be fairly expensive i would guess, so they will wait for next year when i've recovered from the current spending.  Another thing i also desperately need now is a proper diff, also going to have to wait until next year. First gear is pretty much useless now, and second will spin up if i let it   Got a few videos from the trackday, first off is just a drive by, being a bit lairy going into the corner like a trike and missing the apex, but it's all good fun!  Drive by  The rest are in-car footage. First time at the track so as the sessions go on i start learning the lines a bit more etc. I still have the odd play about with lift off oversteer showing off to various passengers. There were a few quick cars there, i was quite impressed with the two R32 skylines which i came across, no idea whether they were standard or had been played with but definitely very capable cars! (Sessions 3 and 8 show them, I also get an Alfa Romeo Black flagged in session 11 for 'pushing me off track'  ) )Session 1 Session 2 Session 3 Session 4 Session 5 Session 6 Session 7 Session 8 Session 9 Session 10 Session 11 ________________________________________ Goldie the track car. |

|

|

|

welshpug! welshpug!

Capt Pedantic Location: Bigend, Wales. Registered: 27 Mar 2007 Posts: 25,839 Status: Offline |

Post #642

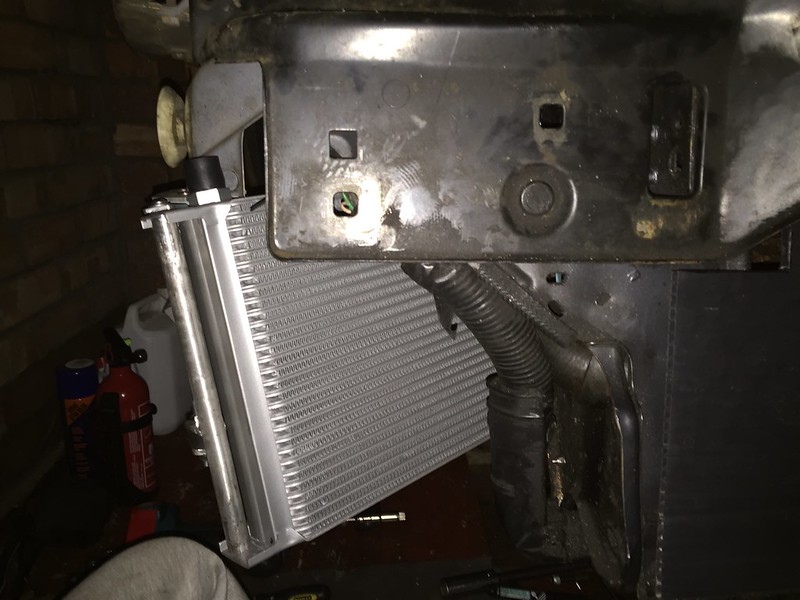

rad looks fine, though the MASSIVE intercooler blocking it wont help  have you checked the charge temps? I noticed theres quite a gap above the rad, filling that in will help, most of the air will try going straight over the top, filling in the sides to the bumper will help too, separatethe lower grille from the fog lamp holes. ________________________________________ need a part number? get on here - http://public.servicebox.peugeot.comBring on the Trumpets. |

|

|

|

prism7guy prism7guy

Seasoned Pro Location: DoncastAAAAARGH Registered: 13 Jan 2008 Posts: 4,640 Status: Offline |

Post #643

I havent checked the charge temps, but if the manifold temperature after a session on track is anything to go by it's pretty cool. (Just above ambient, i'll shove a thermo probe in next time i get the car out and see what that says).The radiator has shroud all round it blocking off most of the air ways between the radiator and the slam panel, sides and cross member. I see your point about extra material to block off the fog lamp holes and add some to force air from the grille into the rad. I'm also considering doing what Jim Davey has done with some louvres into the wheel arches to try and lower the engine bay pressure, which should mean more air will easily flow through the intercooler and radiator increasing the cooling capacity. ________________________________________ Goldie the track car. |

|

|

|

phillipm phillipm

Seasoned Pro Location: Rotherham Registered: 15 Oct 2006 Posts: 20,607 Status: Offline |

Post #644

I still think you need more bonnet catches.________________________________________ - Bespoke rollcages/additions/adjustments. Half cages right up to complete custom spaceframes - MSA/FIA spec, CDS, ROPT, T45, etc - PM meEmail me! Custom-made polybushes available - need an odd size or fitment? - anything from batch work to one-off pieces. |

|

|

|

MisterGTR MisterGTR

Senior User Location: Glasgow Registered: 05 Aug 2014 Posts: 675 Status: Offline |

Post #645

I don't have OCD but that steering wheel bothers me!  ________________________________________ Turned 40 and in true cliched fashion buying one of the cars of my teenage dreams! |

|

|

|

prism7guy prism7guy

Seasoned Pro Location: DoncastAAAAARGH Registered: 13 Jan 2008 Posts: 4,640 Status: Offline |

Post #646

phillipm wrote: I still think you need more bonnet catches. They're all on back order  MisterGTR wrote: I don't have OCD but that steering wheel bothers me!  Yeah it's started to bother me too, i'll look into sorting it if i get chance this weekend. Don't suppose you know either of them R32 drivers do you Ian? Would be interesting to see if they have project threads and what they've done to their cars.  ________________________________________ Goldie the track car. |

|

|

|

phillipm phillipm

Seasoned Pro Location: Rotherham Registered: 15 Oct 2006 Posts: 20,607 Status: Offline |

Post #647

It was straight until he called in the burger van.________________________________________ - Bespoke rollcages/additions/adjustments. Half cages right up to complete custom spaceframes - MSA/FIA spec, CDS, ROPT, T45, etc - PM meEmail me! Custom-made polybushes available - need an odd size or fitment? - anything from batch work to one-off pieces. |

|

|

|

prism7guy prism7guy

Seasoned Pro Location: DoncastAAAAARGH Registered: 13 Jan 2008 Posts: 4,640 Status: Offline |

Post #648

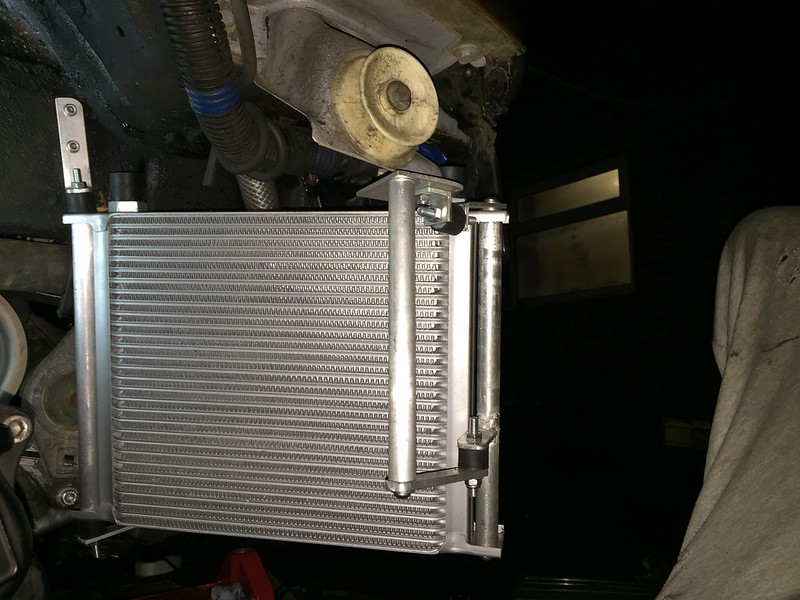

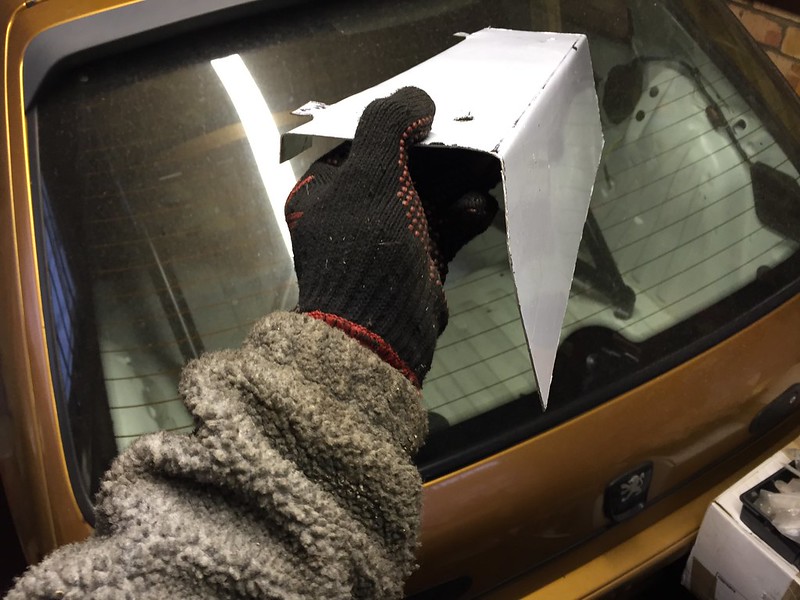

Time for another small update.Not an awful lot has been done to the car since the last trackday, but i've made a little start on sorting some of the older issues and found some fresh ones. To help sort out the oil temperature on track i decided to get an oil-air cooler to fit between the engine and the laminova. I got a little carried away and went overkill, but my theory is that this should be capable of bringing the oil temperature right down, then the laminova will then put a decent amount of heat back into the oil before it goes through the filter and back into the engine where it will then be circulated. This should also help take some heat out of the coolant and bring that temperature down too.  IMG_6639 by Steve Count, on Flickr IMG_6639 by Steve Count, on Flickr IMG_6638 by Steve Count, on Flickr IMG_6638 by Steve Count, on Flickr IMG_6640 by Steve Count, on Flickr IMG_6640 by Steve Count, on FlickrVery tight squeeze to fit it here, but i couldn't really find anywhere else i could fit it with hopefully decent airflow without having to use a fan. I'm going to make a shroud for this cooler to direct air from the grille/foglight hole. Another thing i've made a start on is a shroud around the radiator to help force more air through that than just escaping round it and into the wheelarch area or under the engine. Still plenty to do to finish this but this is the progress so far.  IMG_6602 by Steve Count, on Flickr IMG_6602 by Steve Count, on FlickrMake-shift sheet aluminium bender   IMG_6663 by Steve Count, on Flickr IMG_6663 by Steve Count, on Flickr IMG_6664 by Steve Count, on Flickr IMG_6664 by Steve Count, on FlickrNext up is quite an annoying problem, the third supercharger now appears to be on its way out and sounds like this   YouTube clicky Looking at the rotor bodies they look to be fine though, and turning by hand i cant feel any backlash or anything untowards. YouTube clicky I could really do with taking the inlet manifold off the charger and having a look at the ends of the rotors as thats where the previous two have failed, although both of them just seized solid without any warning sounds before hand. Anyway, one of the things that i think has caused this failure could be the harsh vibrations that the gears/rotors have to put up with from the crank. Obviously the standard pulley has a rubber damper ring built into it, but my crankshaft pulley is machined from a solid billet of aluminium. Most eaton superchargers have a coupler fitted inside the snout which helps damp out vibrations but due to mine having an electromagnetic clutch as standard i didnt incorporate any real damping into my pulley setup. The standard clutched system did have a sheet of rubber between the friction plate and the plastic end cap to help with vibration, and the end cap itself being a rubbery plastic will have helped. Anyway, enough with the waffling on, i'm now in the process of trying to fit an auto tensioner to help reduce belt slap whilst the engine is varying revs etc, and i've started making some adapters so i can fit a polyurethane coupler to help give some damping to the 'charger. First up i raided the scrap bin at work to make the male and female molds, then smeared them with grease as i'm too tight to buy proper release agents or anything like that   IMG_6620 by Steve Count, on Flickr IMG_6620 by Steve Count, on FlickrThen i mixed up a batch of polyurethane and poured it in.  IMG_6621 by Steve Count, on Flickr IMG_6621 by Steve Count, on Flickr30 mins later it was set.  IMG_6626 by Steve Count, on Flickr IMG_6626 by Steve Count, on FlickrI then made a couple of aluminium plates, one which will bolt to the 'charger pulley and have three dowel pins fitted, the polyurethane coupler will then mate up against this, then the outer alloy plate will have three dowel pins in which fit into the polyurethane coupler, this outer plate will also bolt to the splined adapter which i removed from a spare clutched pulley system. The parts are all turned now and just need the relevant pcd drilling and tapping etc.  IMG_6666 by Steve Count, on Flickr IMG_6666 by Steve Count, on Flickr IMG_6668 by Steve Count, on Flickr IMG_6668 by Steve Count, on Flickr IMG_6670 by Steve Count, on Flickr IMG_6670 by Steve Count, on Flickr IMG_6671 by Steve Count, on Flickr IMG_6671 by Steve Count, on FlickrI've also diagnosed what the knocking was that could be heard in some of the videos from the last trackday, the rear mounting points for my wishbones had some slack in them where the bolt went through the subframe, it became noticeable when accelerating or braking harshly as it would pull the car to one side or the other. I didn't get an accurate measure of the original hole through the subframe but it appeared to be just under 12mm, which i thought was weird as the standard setup uses an m8 bolt to locate the P bush. Anyway, i made like a shouldered washer at work with a 12mm section turned 3mm long, and a snug bore to my mounting cap screws, and ran a 12mm cone drill through the subframe hole, now the setup has no play in it at all even with the nyloc loose on the capscrew, so that should be that issue sorted. That's about it for now, hopefully more updates soon as i need it ready for the pscuk curborough day next month. ________________________________________ Goldie the track car. |

|

|

|

phillipm phillipm

Seasoned Pro Location: Rotherham Registered: 15 Oct 2006 Posts: 20,607 Status: Offline |

Post #649

I used to use an M10 capscrew through there with a big tapered washer so I could crank some torque on without distorting it.________________________________________ - Bespoke rollcages/additions/adjustments. Half cages right up to complete custom spaceframes - MSA/FIA spec, CDS, ROPT, T45, etc - PM meEmail me! Custom-made polybushes available - need an odd size or fitment? - anything from batch work to one-off pieces. |

|

|

|

adam b adam b

Seasoned Pro Location: The Nam Registered: 24 Jan 2006 Posts: 12,828 Status: Offline |

Post #650

Can't wait to see this at Curborough  ________________________________________ Nothing to see here |

|

|

|

The Peugeot GTi-6 & Rallye Owners Club - ©2024 all rights reserved.

Please Note: The views and opinions found herein are those of individuals, and not of The Peugeot 306 GTi-6 & Rallye Owners Club or any individuals involved.

No responsibility is taken or assumed for any comments or statements made on, or in relation to, this website. Please see our updated privacy policy.