Post #22

Moving forward, all heads removed insides drilled out and no movement what so ever...

i'm over it, new options:

1 - due to time restraints go back to Caravel Imports and rush a delivery of the same part without ball joint (Meyle / Swag).

2 - order Ocap / Lemforder part from Euro car part and hope it arrives in time.

3 - put old worn wishbone back on, and wait for new parts, just to get back on the road.

4 - order new wishbone however possible, order full set of Lemforder for when they ware out in the near future supposedly (10% off and discounts on parts ATM, supposedly).

5 - mix of the above to get back on the road, and order a whole new set of Lemforder parts.

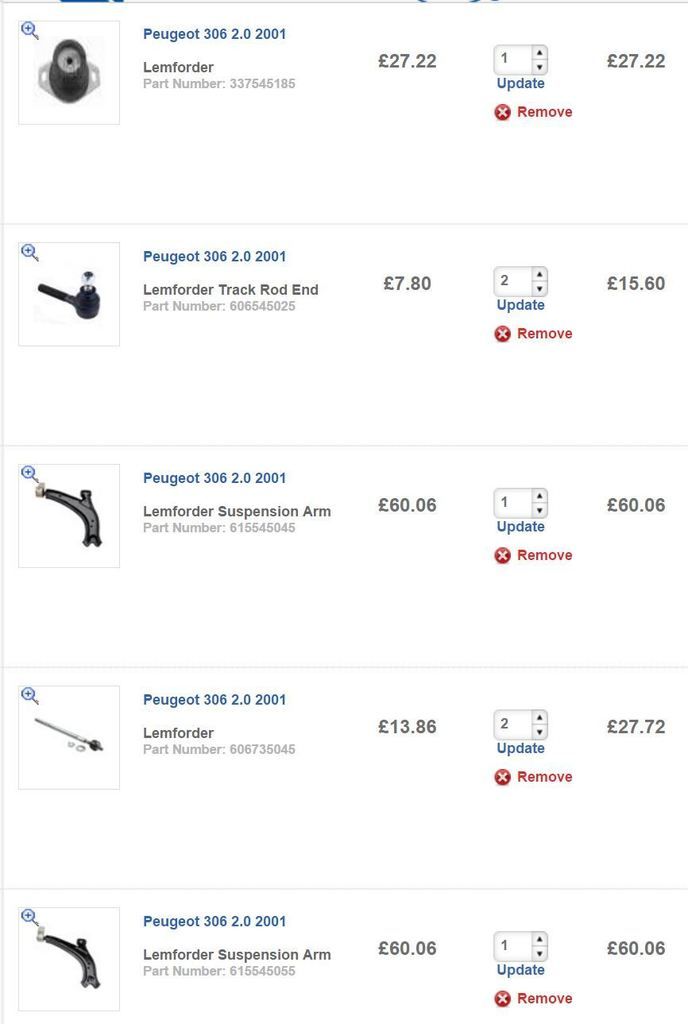

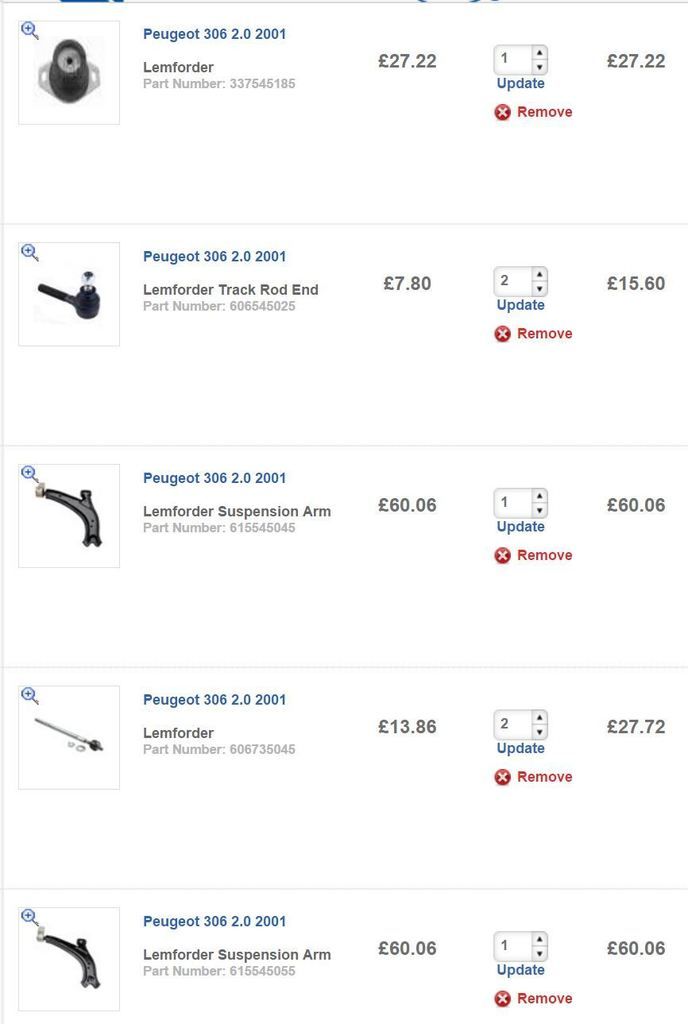

The current order if i go down this path is as pictured, does anyone have anything that should be added, anything and everything is considered, currently front suspension and brakes all round have been replaced with Meyle and Sasic. apart from that everything is OEM from factory, looking for upper right engine mount from Lemforder but it is not listed.

just to reiterate, the problem encountered was simply a bolted on lower ball joint that was not ordered, it came as a whole, all other parts were requested and ordered by a local mechanic.

.

. turns out its 16mm not 18mm

turns out its 16mm not 18mm

doesn't sound to hard drill the bolts out or grind them......

doesn't sound to hard drill the bolts out or grind them......

shabusta

shabusta