The induction stroke causes a drop in air pressure in the intake port as it draws air into the cylinder. The low pressure is essentially the same as the air being 'stretched' because gasses are elastic in nature. Behind a low pressure zone follows a high pressure zone; just as waves in the sea have peaks and troughs following each other.

Harnessing these waves in such a way as to get the positive pressure helping to fill the cylinders is what tuning is all about!!!!

Variable intake lengths do this directly, and this can be seen working in practice on various vehicles including Porsches, with the “varioram” systems. Variable valve timing does this by virtue of setting the wave off at a different point in the cycle so as to manage the positive/negative waves to best effect. Unfortunately, in the Gti-6, as with many older vehicles, we do not have any of these new fangled technologies and as such we have to do it the old school way....

In short, with the exception of reducing friction, tuning is all about harnessing pressure waves, positive ones on the intake and negative ones on the exhaust, particularly on the 'overlap phase'.

So we've all heard about longer duration camshafts, with more lift and we know they are a good thing... but why?

Well, put simply longer duration camshafts work by giving a larger 'window of opportunity' to make better use of the waves we've talked about above. This is simply because the valves are open longer and open earlier. Conversely they offer larger window of opportunity for the negative waves to hinder efficient cylinder filling and scavenging and this is what causes an engine with longer cam durations to be 'off cam' at lower revs. Or, more accurately, the fact is the engine isn't yet in a frequency range (not enough revs) to 'ride the good waves' (man).

To sum up. With short trumpets these waves have less distance to travel, so the time between them is shorter, therefore this suits high rpm better and ultimately makes more power at higher revs. With longer trumpets, the waves have further to travel so the time between them is longer, suiting lower rpm better giving us more torque, and power at lower revs.

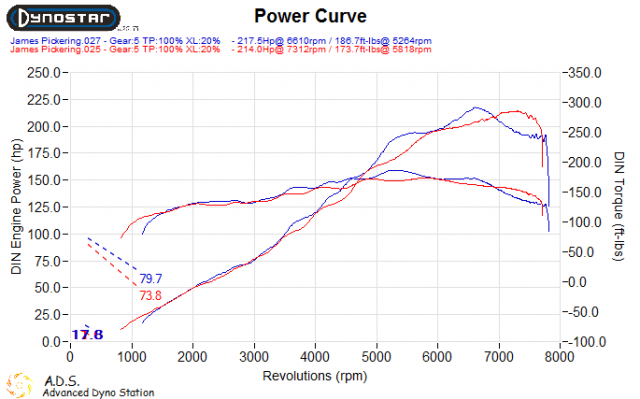

The interesting bit here is when you see two dyno plots overlaid.

Here, you can You can see the shape of the curves are identical, but out of phase with one another and we can see the normal resonance in the torque curve that we see with most throttle body / cam conversions is also “out of phase”.

If we apply our new found knowledge of waves, and resonance in the intake we realise these peaks in our torque curve are all a product of the engine being able to make more power at the points in the rev range where the harmonics are... I.e where the waves are at their peak. As we described above, as we adjust the length of the trumpets we adjust where these peaks are in the rev range – which ultimately moves the harmonics and therefore the peaks in the torque curve.. after all, more air = more power!!!

If we had an unlimited budget, we would have started working the exhaust manifold here, to try and smooth the torque curve, but ultimately engine development costs huge amounts of money... What we are able to do though, is alter the trumpet lengths to move the torque around, as we saw above.

When we have two of the trumpets longer, and two shorter, if we find the right lengths, we can actually pick up different harmonics, or more over pick up harmonics where there are dips on the other cylinders. We effectly find a "middle ground" in the torque curve and fill out the dips.

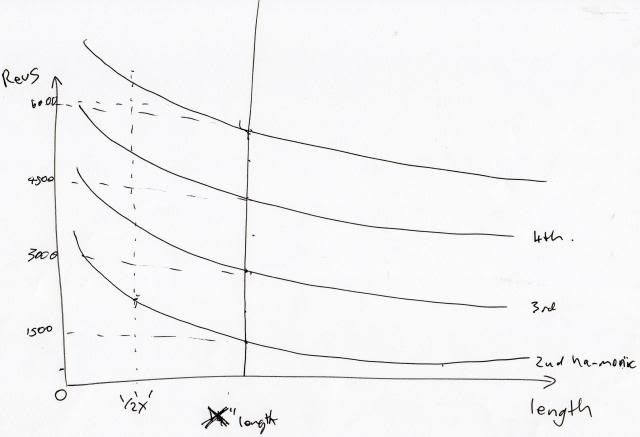

If you see below (yes, it's a hand drawing, I told you this was the old school way!) you'll see this.

In the graph, you see inlet length (trumpet length) along the x axis, and revs (rpm) along the y axis. The curved lines on the graph show the harmonics of the inlet pulses. I haven't included the 1st harmonic, as it's so long that you'd probably need a 10 metre inlet length to catch it!

It's pretty obvious to see the relationship between harmonic and revs is relational to the length of the trumpet. The shorter the trumpet, the higher up the revs we see the harmonic.

The key point here, is the dotted line and solid line intersecting the graph. It has been oversimplified a bit here, but with trumpet length x, in my diagram we see the harmonics at 1500rpm, 3000rpm, 4500rpm and 6000rpm. With ½ X (I.e half the trumpet length) we see the harmonics at, 2250rpm, 3750rpm, 5250rpm and 6750rpm.

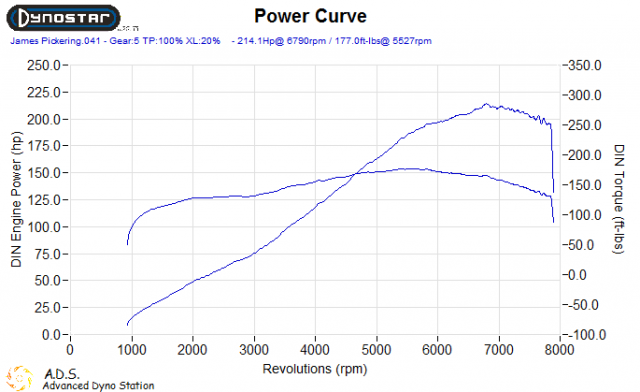

If we can tune these inlet lengths so that they are exactly half a harmonic out from each other (2 cylinders at one length, 2 cylinders at another length) we can effectively fill the troughs in the torque curve with power, however we do also lose our peaks - hence the peak power is marginally lower.

What's important though, is area under the curve. Clearly, the more the better, and by filling the troughs we make the car smoother and more drivable.

Below is the outcome of the staggered trumpets:

and a couple more piccies of the build:

________________________________________

HDI Engine Tuning / Remapping Services - https://www.facebook.com/dervtech306 GTi-6 Track Car - 200+ hp all N/A!

306 DTurbo Track beasty - 209.9hp - RIP

jammapic

jammapic