________________________________________

See the sheer power and might of the lesser known burrowing owl.

|

| Author | Subject: Goldie the track car |

aaron6 aaron6

Seasoned Pro

Location: On the sofa in maidstone Registered: 16 May 2006 Posts: 5,840 Status: Offline |

Post #776

Maybe do a February one and I might be able to take part. The wife said no March dates as she could drop anytime during. |

|

|

|

armzsc6 armzsc6

Seasoned Pro Location: Crowborough Registered: 22 Mar 2008 Posts: 3,445 Status: Offline |

Post #777

Understand that but brands isn't more than a few minutes up the road and you could drive straight off the track onto the road to the hospital if she decides to pop. Not like your car isn't road legal  . . Was just thinking March will be better weather slightly less freezing cold track bit more grip etc ________________________________________ Black power baby! SUUUUUPERCHARGED Seat Leon FR TDI 190BHP 300lbft daily gti-6 killer :p 12x 306's owned so far Cambelts, clutches, service work carried out on All makes and models, Peugeot Citroen / mitsubishi specialist. Pug planet / Citroen Lexia diagnostics / code reads available. |

|

|

|

aaron6 aaron6

Seasoned Pro

Location: On the sofa in maidstone Registered: 16 May 2006 Posts: 5,840 Status: Offline |

Post #778

Can do after March. She has explicitly ruled out anything in March.  ________________________________________ See the sheer power and might of the lesser known burrowing owl. |

|

|

|

demondriverdan demondriverdan

Seasoned Pro Location: Londinium Registered: 29 Nov 2010 Posts: 2,665 Status: Offline |

Post #779

Plus you'll already be in "track mode" so will drive even faster to the hospital  ________________________________________ Rallye Race Car |

|

|

|

armzsc6 armzsc6

Seasoned Pro Location: Crowborough Registered: 22 Mar 2008 Posts: 3,445 Status: Offline |

Post #780

demondriverdan wrote: Plus you'll already be in "track mode" so will drive even faster to the hospital  This  ________________________________________ Black power baby! SUUUUUPERCHARGED Seat Leon FR TDI 190BHP 300lbft daily gti-6 killer :p 12x 306's owned so far Cambelts, clutches, service work carried out on All makes and models, Peugeot Citroen / mitsubishi specialist. Pug planet / Citroen Lexia diagnostics / code reads available. |

|

|

|

aaron6 aaron6

Seasoned Pro

Location: On the sofa in maidstone Registered: 16 May 2006 Posts: 5,840 Status: Offline |

Post #781

________________________________________ See the sheer power and might of the lesser known burrowing owl. |

|

|

|

prism7guy prism7guy

Seasoned Pro Location: DoncastAAAAARGH Registered: 13 Jan 2008 Posts: 4,640 Status: Offline |

Post #782

Had a decent day at Brands Hatch, it was icy to start with so they spread grit on the track during the briefing, the track was wet to start with, meaning grip was almost non-existent. I spent the morning learning the track and getting used to the increasing grip levels as dry lines started forming in some areas. IMG_7689 by Steve Count, on Flickr IMG_7689 by Steve Count, on FlickrHere's a few clips i recorded during the day: Clip 1 Clip 2 Clip 3 Trying to keep up with a Nissan GTR Final session, it rained so a very greasy track with plenty of lift off oversteer  ________________________________________ Goldie the track car. |

|

|

|

rwgti rwgti

Seasoned Pro Location: Yorkshire Registered: 08 Jul 2008 Posts: 1,727 Status: Offline |

Post #783

Looks slow that mate. You sure your supercharger is working?________________________________________ Team Astor Grey Supercharged GTI 6 |

|

|

|

prism7guy prism7guy

Seasoned Pro Location: DoncastAAAAARGH Registered: 13 Jan 2008 Posts: 4,640 Status: Offline |

Post #784

Nah, i left it uncoupled to make sure i didn't break anything again!  ________________________________________ Goldie the track car. |

|

|

|

prism7guy prism7guy

Seasoned Pro Location: DoncastAAAAARGH Registered: 13 Jan 2008 Posts: 4,640 Status: Offline |

Post #785

Not updated this thread for a while. To be honest i've not really done much to the car until the last month or so, other commitments have got in the way.Last month i took it to the PSCUK Curborough sprint day though and got the love back for it. Few pictures i've shamelessly stole from the photographers there, thanks for the images if you took them   IMG_8045 by Steve Count, on Flickr IMG_8045 by Steve Count, on Flickr IMG_8037 by Steve Count, on Flickr IMG_8037 by Steve Count, on Flickr IMG_8046 by Steve Count, on Flickr IMG_8046 by Steve Count, on Flickr IMG_8049 by Steve Count, on Flickr IMG_8049 by Steve Count, on Flickr IMG_8058 by Steve Count, on Flickr IMG_8058 by Steve Count, on FlickrAnd a few videos: Session 1 Session 2 Session 3 Session 4 Session 5 Session 6 I developed a mis-fire by the end of the day which was a shame as i much prefer the figure of eight layout, one of the bolts from the satchshift also fell out, the one that goes through the rose joint below the gearstick, hence why i was struggling to find gears at one point. Luckily someone had a bolt spare so i bodged it back together and made it back out later in the day. Since getting home i've replaced that bolt and used plenty of loctite on the new one, hopefully resolving that issue. I'm sure i used loctite originally as Damien mentioned he'd had some come loose when i was fitting mine, but this time i've used loads!  As for the mis-fire, i've whipped the plugs out and found this:  IMG_8038 by Steve Count, on Flickr IMG_8038 by Steve Count, on FlickrDoesn't look ideal, the manky one is from cylinder 4 (cambelt end). I've done a compression test, and got the following pressures: Cylinder 1 = 200psi Cylinder 2 = 200psi Cylinder 3 = 220psi Cylinder 4 = 210psi So there doesn't appear to be anything major untowards there i don't think. I've ordered a new set of plugs anyway so when the car goes back together i'll fit them and see whether that was the cause of the misfire, it only seemed to do it above 4,500rpm. On the drive home i ran out of front pad material on one of the pads, no major issue as i just used the gears and handbrake to knock off the speed until i got home, barely any damage to the rotor so i think i'll just leave them as they are. I've ordered and fitted some new Carbotech XP8 pads. I've also removed the header tank, when i was making it i ran a tap through the expansion take-off port as i'd got a bit of weld in there, but i ran the tap too far in and damaged the sealing face for the pressure cap:  IMG_8057 by Steve Count, on Flickr IMG_8057 by Steve Count, on FlickrI'm hoping that this is the cause for losing coolant into the expansion bottle whenever i give the car a bit of grief, it's always fine if driven sensibly on the roads. Anyway, i've tig'd up the damage then milled the entire surface to hopefully get a better seal in the future, and i've also bought a new radiator cap, 20psi relief again but this one came with a rubber seal which rests on the top face of the filler neck, which i'm hoping will create a good enough seal so any coolant that makes it into the expansion tank in the future will be drawn back into the header tank as the car cools. The old cap just had a piece of aluminium to try and create the seal.  IMG_8060 by Steve Count, on Flickr IMG_8060 by Steve Count, on FlickrThere are a few other things going off in the background for the car but i don't want to go into them until i've made some proper progress and have something decent to show for my efforts. The next installment should be soon enough though, here's a little teaser of what it involves...    IMG_8078 by Steve Count, on Flickr IMG_8078 by Steve Count, on Flickr________________________________________ Goldie the track car. |

|

|

|

RallyeRed RallyeRed

Regular Location: Northwich Registered: 03 May 2016 Posts: 353 Status: Offline |

Post #786

Good to see you're back on it -looking forward to more updates this year  |

|

|

|

prism7guy prism7guy

Seasoned Pro Location: DoncastAAAAARGH Registered: 13 Jan 2008 Posts: 4,640 Status: Offline |

Post #787

Cheers, ive got to say though, your project thread is one of the things that's given me the kick up the backside to crack on with my own  ________________________________________ Goldie the track car. |

|

|

|

phillipm phillipm

Seasoned Pro Location: Rotherham Registered: 15 Oct 2006 Posts: 20,607 Status: Offline |

Post #788

Stick a nord-lock on the shift bolt, screwfix are doing their own el-cheapo version in smaller sizes now. Probably not as good as the proper ones but handy in a hurry.________________________________________ - Bespoke rollcages/additions/adjustments. Half cages right up to complete custom spaceframes - MSA/FIA spec, CDS, ROPT, T45, etc - PM meEmail me! Custom-made polybushes available - need an odd size or fitment? - anything from batch work to one-off pieces. |

|

|

|

prism7guy prism7guy

Seasoned Pro Location: DoncastAAAAARGH Registered: 13 Jan 2008 Posts: 4,640 Status: Offline |

Post #789

Ah, I forgot to put one of them on, ive got a few spare from last time I needed one. That's a job for tonight then!  ________________________________________ Goldie the track car. |

|

|

|

prism7guy prism7guy

Seasoned Pro Location: DoncastAAAAARGH Registered: 13 Jan 2008 Posts: 4,640 Status: Offline |

Post #790

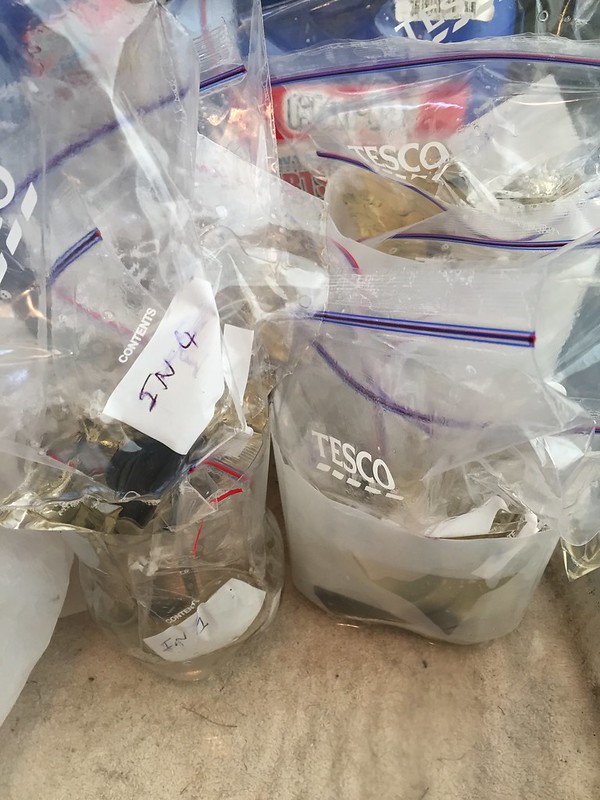

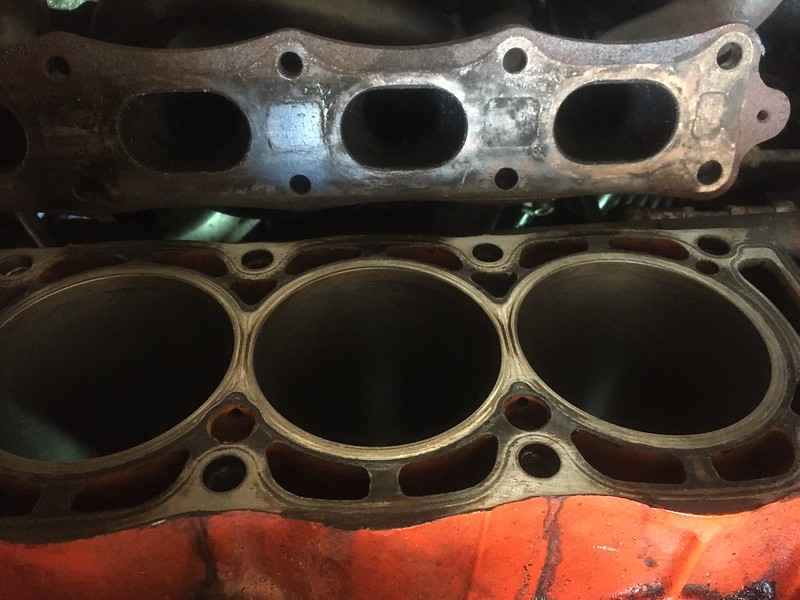

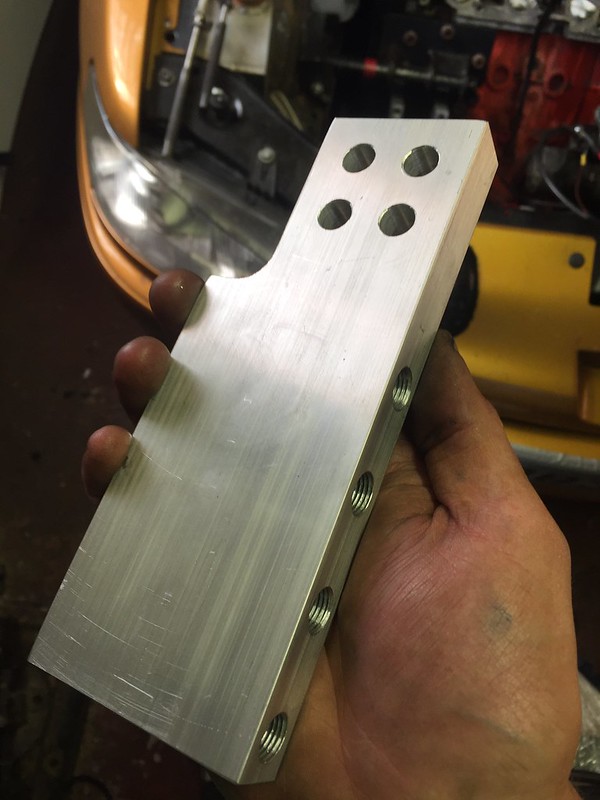

Update time:I put a nord-lock and loctite on the satchshift bolt, it hasn't come out since then   IMG_8044 by Steve Count, on Flickr IMG_8044 by Steve Count, on FlickrI'd also ordered myself a 3J limited slip diff, it took a while to arrive as 3J were waiting on some shims to get in stock, anyway, it finally arrived so i skimmed out the gearbox housing where necessary using a flap wheel and stuck that in. I went for 40/90 ramp angles with around 65-75 lbft preload. It seems pretty good so far.  IMG_8127 by Steve Count, on Flickr IMG_8127 by Steve Count, on FlickrAfter fitting the diff i took the car out for a quick test, the diff made the world of difference but it became apparent that the head gasket had gone as the coolant was still bubbling out of the header tank even after making sure the cap got a good seal. Off came the head:  IMG_8169 by Steve Count, on Flickr IMG_8169 by Steve Count, on Flickr IMG_8174 by Steve Count, on Flickr IMG_8174 by Steve Count, on Flickr IMG_8176 by Steve Count, on Flickr IMG_8176 by Steve Count, on FlickrI took the head off to a local engine machine shop, told them to do the minimum skim possible, ultrasonic clean it, fit all new valve guides and do 3 angle valves and seats. Whilst the head itself was away i turned the dining room into the parts cleaning area, i bought a big plastic tub and a bottle of parts cleaner and got to work with an array of brushes.  IMG_8179 by Steve Count, on Flickr IMG_8179 by Steve Count, on Flickr IMG_8180 by Steve Count, on Flickr IMG_8180 by Steve Count, on FlickrBefore the head removal i had a ticking sound that would disappear after a short while, which i put down to a hydraulic lifter. I stripped each one down completely and left it soaking in clean parts cleaner fluid for 3 days, agitating each pot every few hours. I was anal about making sure that each one went back together with the parts it was originally built up with, and that each assembly would go back into the head in the same position it came from. After a few days of soaking in the cleaner i got a clean cotton bud for each one and gave them a good clean.  IMG_8182 by Steve Count, on Flickr IMG_8182 by Steve Count, on Flickr IMG_8183 by Steve Count, on Flickr IMG_8183 by Steve Count, on Flickr IMG_8185 by Steve Count, on Flickr IMG_8185 by Steve Count, on Flickr IMG_8194 by Steve Count, on Flickr IMG_8194 by Steve Count, on FlickrFor reassembling i got some fresh engine oil, put a couple of drops inside the pressure relief valve, put the spring in, pushed the piston in whilst depressing the relief ball with a wooden cocktail stick and cycled that a couple of times to make sure it moved free, then smeared more oil on that and pushed that assembly back into the bucket, once again giving it a couple of drops of oil. The piston was nice and springy on each one i built.  IMG_8188 by Steve Count, on Flickr IMG_8188 by Steve Count, on Flickr IMG_8197 by Steve Count, on Flickr IMG_8197 by Steve Count, on Flickr IMG_8204 by Steve Count, on Flickr IMG_8204 by Steve Count, on FlickrNext up came my worst nightmare. When i removed the head i measured it from the head gasket face to the cam carrier mating face, it was 137mm which i was happy about, meaning the head had never been skimmed before. I went to collect the head from the machinists after over a week of being messed around and plenty of false promises. When i went to pick it up i asked the guy who machined it how much he had skimmed off, to which he replied 'the maximum, 30 thou (around 0.75mm). My face must have said it all as his face then dropped and i informed him i'd asked for the minimum skim. I wasn't overly happy at this point to say the least. At this point i was due to go to the nurburgring on the friday and this was the tuesday before. The machinist then went and read my letter that i left with the head and saw that i'd asked for the minimum skim and that it was someone else who had told him to do the maximum and messed everything up, admitting the fault was their end they offered to do the same service to another head if i could source one and try to get it done in time. After a phone call to a mate i had sourced a new head which i went and collected that evening, but upon getting home and measuring that it was down at 136.4mm, so it had obviously been skimmed once or twice before and would be no use if it was skimmed again. It was pretty late in the evening at this point, but after a bit of thinking of ways to resolve the problem i decided to get the pistons and rods out and have the valve pockets deepened. It was around 3:30am by the time i'd got the sump off, oil pump out, windage tray off then undone the big-ends and pushed the pistons up out of the block. I dropped the pistons off at my dads house then drove home and got a couple of hours sleep before work the next day. As soon as my dad had dropped the pistons off i called them and said exactly what i wanted doing, basically pocketing 1mm deeper and moving out 0.5mm from the centre of the piston to accomodate the valves essentially being further apart in relation to where the original valve cut outs were. That afternoon i called them back and they said that they had done the machining, sourced me new piston rings and big end bearings and that i could collect it all that evening, they also lent me their flexi hone and tool for inserting the pistons into the block all at no expense to me. By this point it was thursday afternoon and all i had was a block bolted into the car, a head that i'd built up as far as inserting all the valves, stem seals, springs and collets and put the hydraulic lifters in the correct bores. Luckily a mate who had flown over from america specifically for the 'ring trip was willing to help out, and another mate Tom offered his assistance which was gratefully accepted and the three of us set about honing the block, putting the spray bars back in, fitting the piston rings, dropping the pistons in, fitting the new big end bearings, then i set about refitting the windage tray, oil pump and sump whilst Tom and Joe set about fitting the head and attaching the manifolds etc. I think we called it a day just after midnight, but the vast majority of work had been completed, just basic pipework, hoses and fluids needed adding by this point, but it was too late to try starting it anyway so i left that for the morning. Friday morning came round so i dashed out to the garage, finished off all the bits that needed doing then set about getting my clothes packed and tools etc for the 'ring trip. I put in a bottle of running in oil and drove it down to the fuel station, then back to work to sort out what needed doing when i got back from holiday as the boss would then be away, then drove home only to notice oil p**sing out everywhere from one of the cam seals. Off came the cambelt cover, off came the cambelt and exhaust pulley, in went a screwdriver into the seal, ripped it out and fitted a new one, back went the pulley, on went the cambelt, out came the running in oil and filter and in went some cheap nasty mineral oil and a new filter.  IMG_8214 by Steve Count, on Flickr IMG_8214 by Steve Count, on Flickr IMG_8223 by Steve Count, on Flickr IMG_8223 by Steve Count, on Flickr IMG_8228 by Steve Count, on Flickr IMG_8228 by Steve Count, on FlickrI ran the engine in on the mineral oil on the way to Germany, basically just going up and down the revs as much as i could without loading the engine too heavily, first keeping the revs low then as the journey went on allowing them to go higher. I didn't let the engine idle once when i was sat in traffic, much to the annoyance of everyone around i would just sit blipping the revs.  Once I got to Germany i dropped the mineral oil, removed that filter and fitted a new one then filled the system with the oil i normally run. The car seemed a bit sluggish so i checked the cam timing and sorted that out, the car ran pretty nicely after that. I did a few laps but it was high 20's to low 30c temps, so the coolant was getting very hot after a couple of minutes on track, afraid i'd fry the new head gasket i'd have to back off for a couple of minutes to bring it back down before going for it again. Very frustrating as i'd have to wait until late in the day to get the laps in. After a few days of this i took the bumper off and attacked it with a knife   IMG_8327 by Steve Count, on Flickr IMG_8327 by Steve Count, on FlickrSurprisingly that made the temps stable around 95c, higher than i'd like but good enough that i can go flat out and they wouldn't get any higher. I'd also noticed i was a couple of psi down on boost, at first i assumed it was because of the altitude and the air being thinner, then i got a can of brake cleaner and sprayed it at the inlet manifold whilst it was idling and there seemed to be a leak between cylinder 1 and 2. To try and sort this i was nipping up the nut and cap screws that clamp the manifold to the head and before it sealed the manifold cracked. Bugger. Fortunately a mate called Dan (DCC, old member on here) was heading out to the 'ring so i messaged him and asked him to bring some RTV or any kind of sealant, which he did so i smeared that all over the crack which seemed to slightly help for a while.  IMG_8277 by Steve Count, on Flickr IMG_8277 by Steve Count, on FlickrAnd a pic of the car on the 'ring   IMG_8278 by Steve Count, on Flickr IMG_8278 by Steve Count, on FlickrAfter a week in Germany it was time to head off to Le Mans. Around an hour away my afr started to go all over the place, running leaner than i was happy with so i pulled in and had a look around, unable to find anything obviously wrong. I wasn't sure whether it was because i'd just stuck a bottle of octane booster in which i thought maybe the wideband didn't like. After the quick stop the car seemed a little happier but i kept the speed down, then pulled in 30 mins later to fill up with fuel again. At that petrol station there was a nasty noise coming from what sounded like the supercharger, so off came the bonnet. After a quick inspection it became apparent that the bracket that held the alternator tie rod in place had snapped then moved against the auto tensioner pulley and was chewing it up. Out came the tools, off came the supercharger and a make shift alternator tie rod was adapted with a shorter aux belt so only the alternator was being driven by the crank. Unlucky in some ways but at least now in it's n/a form it would run rich when under heavy acceleration, so less chance of det and frying the fresh engine. The car then got me to Le Mans flawlessly, and then all the way home after that weekend. Since then i've made a new tensioner pulley, and re-designed one of the supercharger brackets to also fit the alternator tie rod, this one should be more than up to the job as the previous two have both snapped.   IMG_8395 by Steve Count, on Flickr IMG_8395 by Steve Count, on Flickr IMG_8403 by Steve Count, on Flickr IMG_8403 by Steve Count, on Flickr IMG_8405 by Steve Count, on Flickr IMG_8405 by Steve Count, on FlickrI think that's about all there is to report on it so far. I'm glad i got the diff, and wish i'd got one sooner. I've welded up the inlet manifold but i'm going to skim the mating face when i get chance so it is all flat and won't leak in the future, i think welding the plenum distorted it with all the heat i put into it which caused it to warp. I used a 5mm thick PTFE gasket between the inlet manifold and head after making the manifold, but i guess i used all the compression there was to give the first time i nipped up the manifold and this second time there wasn't enough there to give a good seal without applying too much force which snapped the tab off the manifold. I'm hoping to get the car back together to take to pugfest but i'm a bit concerned about the afr readings, i'm not sure whether it was the octane booster (but the engine ran like crap when it claimed to be lean which must mean the afr gauge was right), or if the throttle position sensor is knackered, or whether the fuel pump isn't supplying enough pressure, or whether there's an issue with the fuel pressure regulator. My money is on the throttle position sensor as i was messing about on the drive home with the throttle pedal, around 4,000rpm the afr would sit at 13.0:1, but if i booted it then went back to try and keep a steady 4.000rpm it would sometimes run richer, and if i'd let off the throttle completely it normally shoots up to off the scale lean, but now it sometimes just sits at 13-15:1, so my theory is the throttle position sensor is giving random readings. I looked on servicebox and they're something silly like £130, if anyone knows of other cars which use the same sensor but have them at a more sensible price please let me know!  I'll add some videos from the 'ring laps when i get chance in the next week or so. ________________________________________ Goldie the track car. |

|

|

|

Day666 Day666

Seasoned Pro Location: Bristol Registered: 20 Apr 2013 Posts: 5,214 Status: Offline |

Post #791

Love the updates ......it's a Great update & read as always  |

|

|

|

adam b adam b

Seasoned Pro Location: The Nam Registered: 24 Jan 2006 Posts: 12,828 Status: Offline |

Post #792

Fair play mate! All that and the 8.20 lap! Well done  ________________________________________ Nothing to see here |

|

|

|

demondriverdan demondriverdan

Seasoned Pro Location: Londinium Registered: 29 Nov 2010 Posts: 2,665 Status: Offline |

Post #793

Cracking read, amazing effort to get the car done in time!________________________________________ Rallye Race Car |

|

|

|

blandy blandy

Seasoned Pro Location: Bucks Registered: 25 Feb 2007 Posts: 2,437 Status: Offline |

Post #794

Same as above cracking read. You've had some pretty s**tty luck as well so hats off for maximum effort |

|

|

|

Chr1sch Chr1sch

Seasoned Pro Location: Worcester Registered: 02 Aug 2014 Posts: 1,025 Status: Offline |

Post #795

Wow fair play you are very handy! I'd have been buggered as soon as it broke the first time lolKeep the updates coming, great to follow progress! |

|

|

|

prism7guy prism7guy

Seasoned Pro Location: DoncastAAAAARGH Registered: 13 Jan 2008 Posts: 4,640 Status: Offline |

Post #796

Cheers for the comments lads  Made a bit more progress recently, welded the inlet manifold back together then machined the mating face nice and flat again. No wonder it didnt seal well, welding the plenum to the standard runners must have twisted it quite a bit as it needed 0.75mm taking off to fully clean up!  IMG_8401 by Steve Count, on Flickr IMG_8401 by Steve Count, on Flickr IMG_8408 by Steve Count, on Flickr IMG_8408 by Steve Count, on Flickr IMG_8409 by Steve Count, on Flickr IMG_8409 by Steve Count, on Flickr IMG_8411 by Steve Count, on Flickr IMG_8411 by Steve Count, on FlickrI've also welded a small clevis to the underside of the plenum which will accept a rose joint, i'm just waiting on a pair of rose joints to make up a link bar which will help support the manifold to the block which will put less strain on the manifold to head capscrews in the future, as i'm sure i must put a bit of stress on them when i'm riding kerbs on track  Heres a link to one of the nurburgring videos, my new PB at 8:22BTG  Clicky More links to come shortly. ________________________________________ Goldie the track car. |

|

|

|

prism7guy prism7guy

Seasoned Pro Location: DoncastAAAAARGH Registered: 13 Jan 2008 Posts: 4,640 Status: Offline |

Post #797

I've not updated this for a while, mainly because updating 32 pages with fresh image links is pretty daunting and it's taken me literally tens of hours to find the pictures, upload them to flickr then go through each post editing out the old links and putting in the relevant new link.Anyway, that's all done now so time for a small update. As promised, here's another link to a 'ring video. I ran out of talent and grip at one point so did a little grass cutting, but i find it an entertaining watch non-the-less. Clicky I also found a snippet of goldie that made it into someones compilation  Clicky I did get a picture of the supporting clevis that i mentioned in a previous post, and made a link system which helps support the weight of the inlet manifold to the block, but that was on my old phone which died a horrible death. I might try and get a new photo next time i go out to the garage. Since the nurburgring i took the car to a couple of local shows, just for a run out with the Yorkshire PSCUK group. The fueling issue seemed to have disappeared until after a recent trackday at Cadwell. It seems that getting the car hot and giving it abuse seems to trigger it to either want to run lean or rich at random. I'm hoping that replacing the TPS with a new one will resolve this for next year, although i think i'm going to also take the car to the guy who mapped it and ask him to just double check the map and tweak it as necessary incase the ignition is now a bit aggressive with the higher compression ratio. I also fancy putting the smaller pulley on to give a little more oomph for the time being. Here's some footage from Cadwell: Session 1 Session 2 Session 3 Session 4 Session 5 Session 6 Session 7 The car is now tucked away SORN'd in the garage ready for next year. ________________________________________ Goldie the track car. |

|

|

|

adam b adam b

Seasoned Pro Location: The Nam Registered: 24 Jan 2006 Posts: 12,828 Status: Offline |

Post #798

Dude, the map won't change, so it'll be a sensor or fuel pump or something________________________________________ Nothing to see here |

|

|

|

prism7guy prism7guy

Seasoned Pro Location: DoncastAAAAARGH Registered: 13 Jan 2008 Posts: 4,640 Status: Offline |

Post #799

Yeah, i didn't think the map would cause the fuelling, i reckon its the TPS, assuming it's a wiper running along a carbon or graphite track which i assume has some crap on it which then gives the ecu false readings. I'll probably also chuck in a new temp sensor just to rule that out.I think i forgot to mention that since Germany i fitted a new fuel rail with a brand new Bosch 3 bar pressure regulator in it, and also fitted a fuel pressure sender and gauge. The fuel pressure gauge seems to read fine when it's running rich or lean so i think i can rule out fuel pressure being an issue. From memory it sits at 3 bar under regular conditions then jumps up to 4 bar or above when boosting. (Can't remember the exact numbers but i know it's doing what it should be doing). ________________________________________ Goldie the track car. |

|

|

|

tvrfan007 tvrfan007

Seasoned Pro Location: In the garage Registered: 29 May 2005 Posts: 3,488 Status: Offline |

Post #800

I gotta get me a look at this at some point. Whether I come to a track day to have a nose or we go to the same day I needs to look at this.________________________________________ I'm Si btw Night Blue VW Golf GTD Bianca LBSC Rallye - Track/Road Slag Project Thread Sparkling Silver Mini Cooper D - Super Dooper  - (The other half's wheels) - (The other half's wheels) |

|

|

|

The Peugeot GTi-6 & Rallye Owners Club - ©2025 all rights reserved.

Please Note: The views and opinions found herein are those of individuals, and not of The Peugeot 306 GTi-6 & Rallye Owners Club or any individuals involved.

No responsibility is taken or assumed for any comments or statements made on, or in relation to, this website. Please see our updated privacy policy.