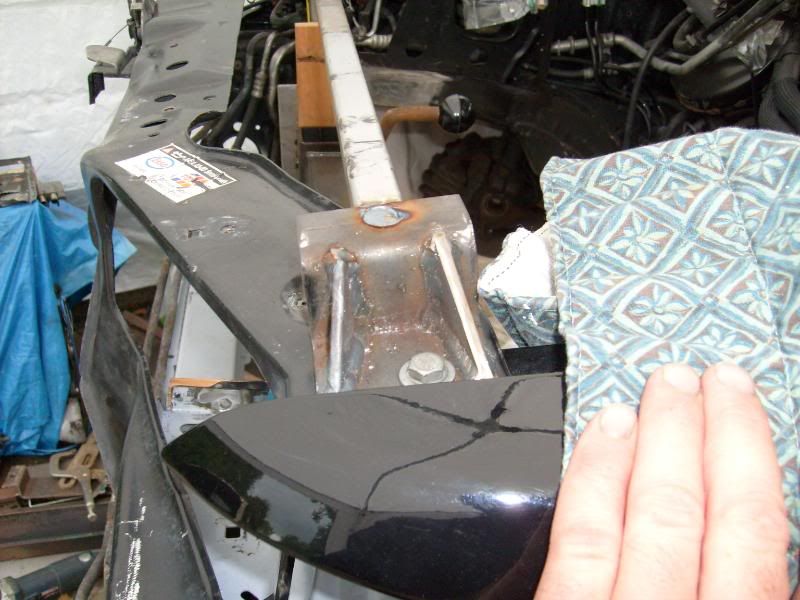

Looking at the sticker on the cross member you can see it's already been replaced once.

They all have that, its the smaller parts sticker that gives the game away, come on Jon, thats a barcode style sticker, unsure what its for though.

Carl

Carl is right, barcode sticker on original crossmember.

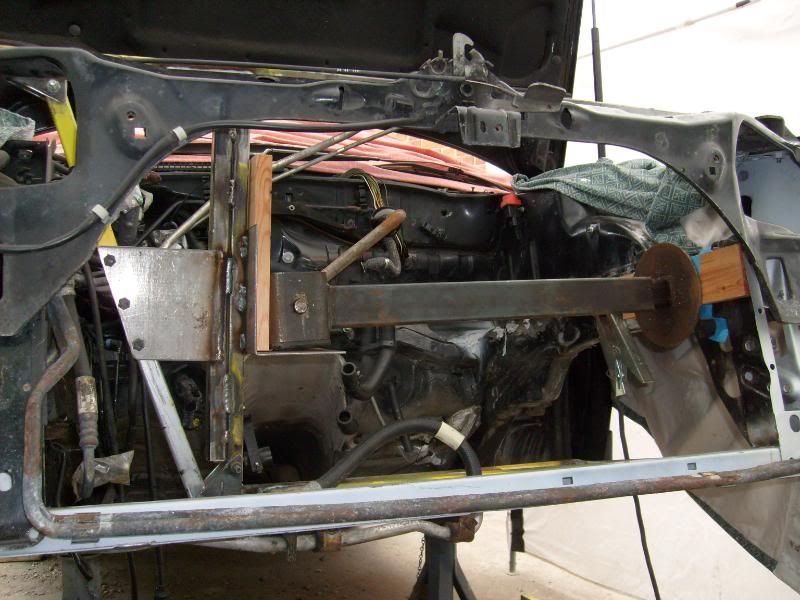

The whack on the N/S was quite hard, so the chances of it not affecting the O/S were slim.

It did not show up in the pictures I have but the chassis was creased with a bulge on both sides and the front bent down.

I thought the best plan would be to cut out the bulged bit,

Straighten it out,

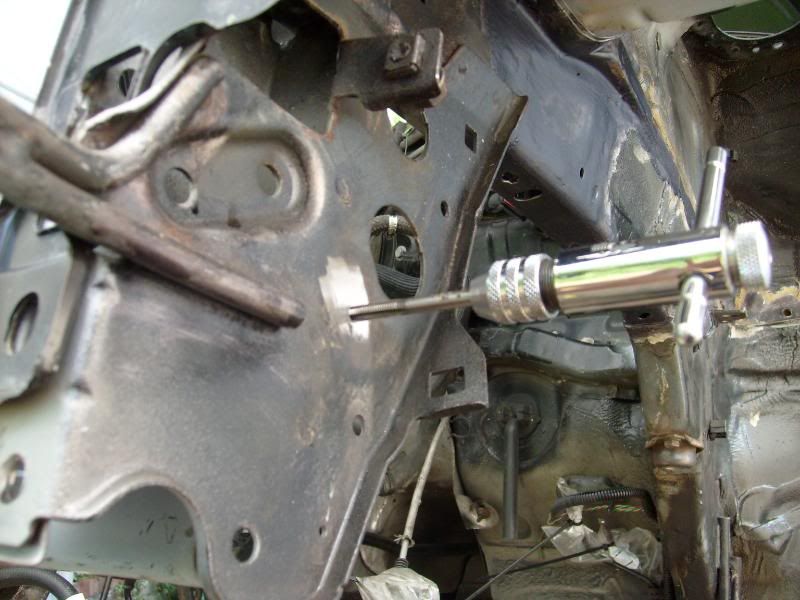

Then 'jig' the chassis back into shape.

My 'jig' is a trolley jack and a lump of wood

Then weld it back in.

I have not done any welding for months, so it is a bit rough looking.

It will look better when I have linished it off and painted it.

I tried on a few panels to check that it all still fitted together. (BTW this was before I jacked up the driver's side)

When I'm done it should look just like it did before I started

________________________________________

Make tea, not war.If it ain't broke......fix it until it is.

tea boy

tea boy

)

)