However it has given me time to get 2000 miles done in the car as a daily commute and touch wood its been totally reliable.

However it has given me time to get 2000 miles done in the car as a daily commute and touch wood its been totally reliable.From the start I decided that I must retain the air con and come up with another way of doing the PAS. For those that don't know the issue you basically sacrifice the air con system to give you room for the Supercharger to fit.

It was suggested from the start that the 106/Saxo electric PAS pump would be a good route and indeed it is. Its a very simple unit which basically uses a 12v supply which runs the pump all the while in ignition position two. I retained the 306's PAS resovoir and used the 106/Saxo pump which has the small remote resovoir (this resovoir was discarded) The other type has the resovoir built into the base of the pump but would have to be fitted horizontally opposed to vertically which in turn would make it difficult if not impossible to fit.

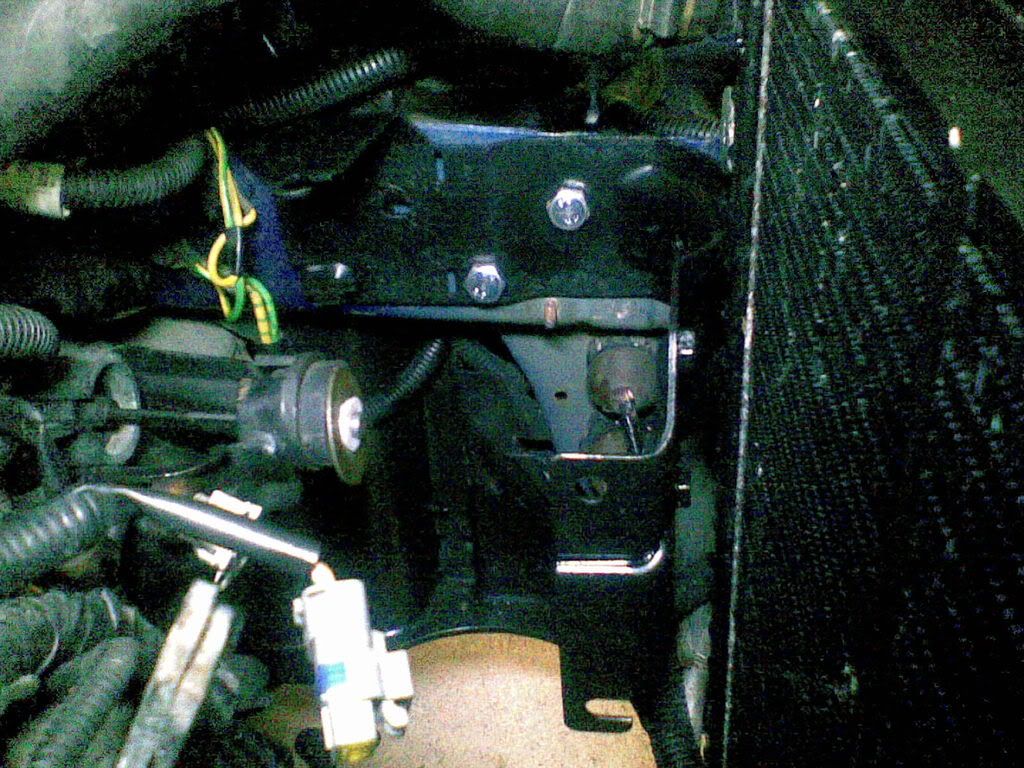

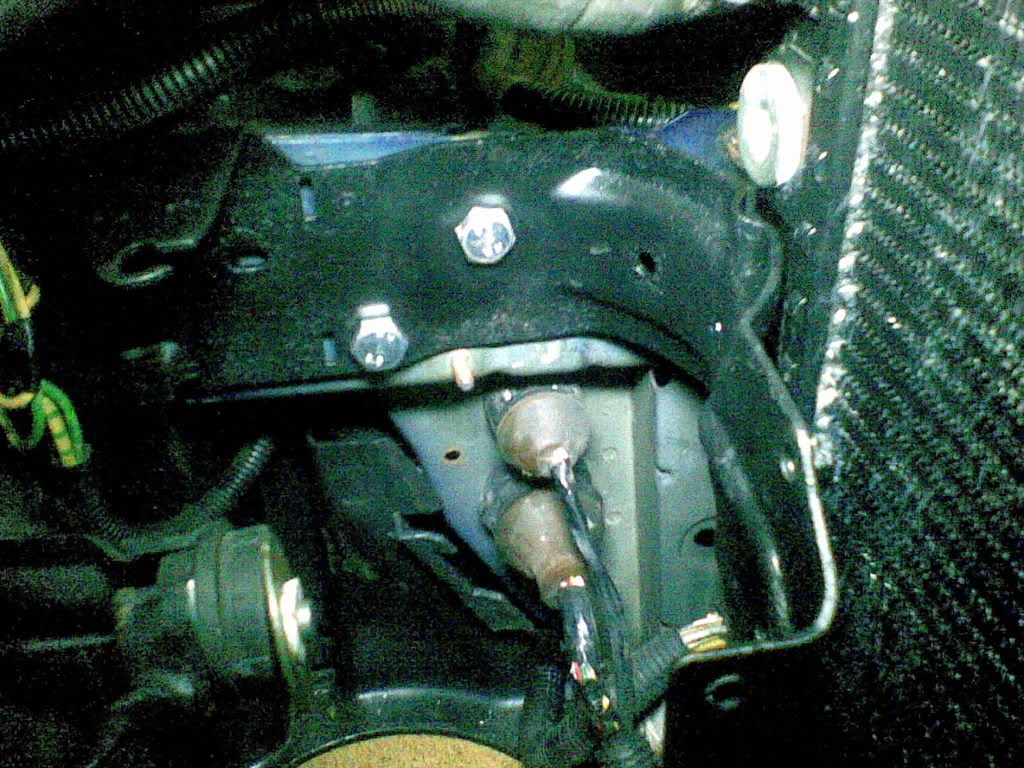

You also need the right angled bracket that comes with the pump and the two metal straps that hold the pump to the bracket. The bracket allows the pump to be fitted nicely into the corner of the engine bay where the standard cars air filter normally takes up residence.

The bracket comes with a handy pair of lugs to hang the superchargers traction fluid resovoir from. Sorry about the image quality, that's late nights and a dodgy camara phone for you, you tend to forget about picture quality when your in the middle of a project.

There is a fair amount of weight to the pump so i ran two M10 bolts through the entire chassis rail section and nyloc'd them to avoid anything working loose over time. The exact position of the bracket is difficult as you have all sorts of odd studs for earthing wires etc in the way plus the radiator etc, then on top of that the bolts need to go through the chassis rail at a point you can get nylocs on the back of them. Treat any holes you drill in the bodywork to prevent corrosion. I would advise using this bracket as you get the anti vibration rubber mounts, mounting the pump directly to the bodywork would give a massive amount of vibration and noise. I was a little concerned that the straps around the pump with the rubber in between wouldn't be enough to hold the pump vertically but seemed to have survived the last 2000 miles without moving, in a rally environment this would be entirely different and additional support would be needed.

Connection to the pump electrically needs to be done via relays as there is a large amount of current supplying the pump under load. I used the short loom that comes from the 106/saxo then routed the 12v supply and relay trigger from the batteries fuse box on the right. I would advise using at least a 40 amp inline fuse and make sure connections to it are good, I got a fuse holder from an old 306 wiring loom. There is a handy bus bar in the fuse box to make your power connections to and one, and only 'one' ignition position 2 wire on the back relay you can piggy back off to trigger the PAS relays.

Yes it does all go back in!

Yes it does all go back in!I've tried driving the car without the pump running which feels great as the feedback from the road is suberb however at parking speeds its obviously heavy and cornering at speed gives you a real workout! I might experiment with some varible force system when i get time but to be fair the electric system feels no different from the mechanical system on all GTI-6's.

Connecting hydraulic wise, if using the 306's resovoir you need to block off one of the inlets in the EPAS (electric power steering unit) plastic body, from memory i ran an M10 or M12 tap in one of the pipes then screwed an M10/12 x 20mm bolt in which has sealed it fine. The other inlet hole is used for the fluid coming in from the 306 resovoir. The piece of pipe RichW sends with his supercharger kit fits nicely on here and runs up to the end of the old pipe which would have gone to the old PAS pump and can be connected using the right angled blue elbow joint supplied. You could of course use the resovoir supplied with the 106/saxo pump but then you have to find somewhere to locate it and you'd still have to route the return from the PAS rack back to the pump so I feel the original route is easier and looks nicer, more OEM.

Now to the tricky bit and i'm sorry I haven't taken photographs. The high pressure hose that used to go to the mechanical pump is long enough to be manipulated to go to the other side of the engine bay to the electric pump. However it screws onto the new pumps outlet but as the outlet is slightly deeper it doesn't bottom out and pinch the pipe olive to make a seal. There are two routes here and after the hassle I had I would favour the first which is to have a new pipe made up by a hydraulics pipe maker to run from the EPAS to the PAS Rack. It could be made exactly to length and have the right elbows etc to fit.

I however ground a few mm from the height of the EPAS outlet after stuffing some tissue inside to stop the fillings going in, this gave the reduced height i needed for the old hose to fit, however when fitting it in situe i managed to strip the threads and crack the outlet. Thankfully a business friend (thanks Channing Engineering) Drilled it all out and made an entirely new steel insert which screws into a bigger hole and works fine. I'm not saying its not possible to go this route but be very careful grinding down the alloy housing its not very strong and easily cross threaded. Going this route also requires that the base of the pump (the plastic part) is unbolted and rotated 90 degrees so that the old hydraulic hose comes into it from the side facing the gearbox, this also requires some deft manipulation of the steel PAS pipe to fit. Like I said earlier I would pay the money and have a pipe made up unless youre really determined.

You can just make out the general direction of the high pressure pipe from the engine to the EPAS.

Once your EPAS system is all in place and working (you can test it without the engine running of course!)you can start on the front end - all those radiators!

Without going into too much detail i junked the original fan and cowling but carefully cut the bottom strip off the original cowling to give me the coolant radiator and air con rad the correctly spaced mounting points but more so something to hold the rubber anti vibration bushes.

I then made some simple brackets from 20mm x 5mm steel to support the intercooler (from Forge Motorsport) click Its the type 05.

You need to mount a pair of slimline Spal fans onto the aircon rad and wire them up to the same cables that supplied the original fans. Use the original fan relay box and tuck it away, I originally chose here.

Which is fine if you have a Rallye but no good if you have spot lights! There is however plenty of room just behind this point.

Once the fans are in place this leaves just enough room to hang the intercooler in front though you will need to take a small chunk out the inside of the bumper either side to allow the intercooler to clear, there is plenty of depth to the bumper and you are only removing about 20mm of plastic to allow the intercooler corners to sit into it.

As a reference I have used the two holes that Peugeot have kindly left either side of the cowling appature on the slam panel.

The metal strip is the stood off the panel by some 20mm spacers which gave the correct distance for the intercooler to clear, on my car anyway! I think its one of those trial and error things which could be individual to every car.

The radiator for the Supercharger traction fluid is then mounted above. It doesn't get a lot of air most of the time but for road use is not really needed, i figured for track use i could remove the plastic slam panel trim that hides it normally to give it as much air needed.

You will notice the green pipe in some pics, this was used to work out the angles/lengths for the boost piping without having to weld then trial it. It was basically irrigation pipe that fitted the alloy boost pipe perfectly. It was then removed and silicon boost pipe joiners used as well as the newly welded aluminium pipe. I tried to keep the flexible joiners to a minimum but you need to bare in mind the engine will move forward and back under load so some flexibility in the pipework will be needed where it meets the fixed intercooler.

The piping from the Supercharger to the intercooler was particularly difficult as it needs to scoot around the aircon pump, its obviously doable but I spent a day on this alone trying to get all the angles correct.

Its tight, early workings for pipe length and angles.

I am considering fitting an oil cooler which would help keep engine temp down for the track, for the road its fine but with the air con rad in the way the coolant rad gets less cool air. It would also allow a bit more room for the Supercharger to intercooler pipe which sits close to the oil filter.

________________________________________

Previous Peugeot - 2000(w)GTI-6, Me old China, Supercharged with working aircon!

toby

toby

). I reckon I spent about 7 days on it, not allowing for bedtime thinking about problems.

). I reckon I spent about 7 days on it, not allowing for bedtime thinking about problems.

Project thread

Project thread

nice post btw

nice post btw