Post #622

So time for another update.

I had a few hours off this week so I got a few bits done.

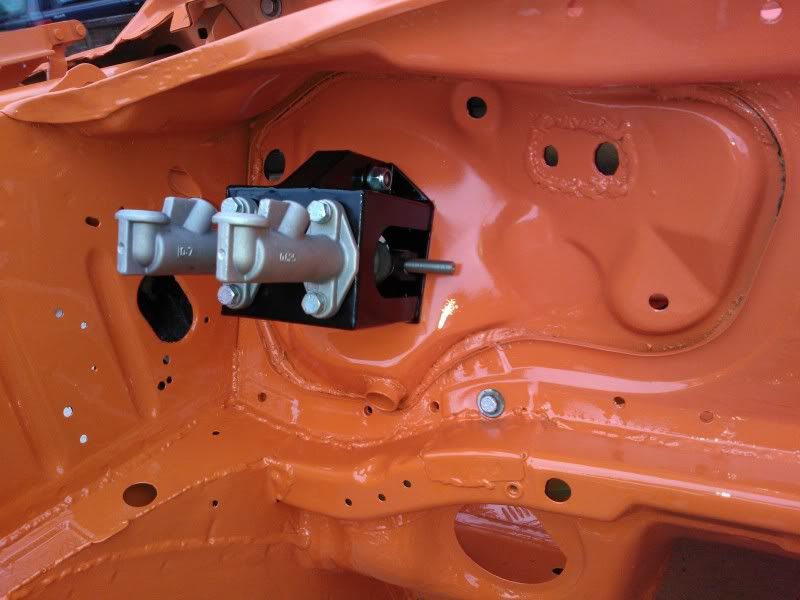

First thing was to fit the power steering reservoir as it was just balanced there.

I couldn't find the captive stud that came out of it, but a good thing about working in IT is a infinite supply of cage nuts.

and with the bolt fitted

and the reservoir is not yellow which is always a bonus

I then got the wire brush out to clean up the trailing arms and ran a tap down all the holes

then a coat of primer.

then a coat or two of black

Then today I set about fitting the new wheels bearings/hub assembly.

I ordered some m8 x15mm high tensile bolts this week to refit the carriers.

put on a bit of loctite

then fitted them, I couldn't find the torque so out came the breaker bar and the got torqued up to FDT.

Then the spacer went on, I can now see why they are almost 30 quid each, they actually seal the rear of the bearing.

according to the Haynes manual you need a hollow drift, but I don't have one, so I used a bit of roll cage that I had laying around.

I then got the nut tightened up, 185 NM is bloody tight so it went in the vice and I managed to do it and then fold the nut down.

I then filled it with grease and attempted to fit the new cover which was too bloody small, bloody E bay so I has to reuse the old one, lucky I have to go to silverlakes tomorrow to find some poverty spec steering column stalks so ill pick another one up then.

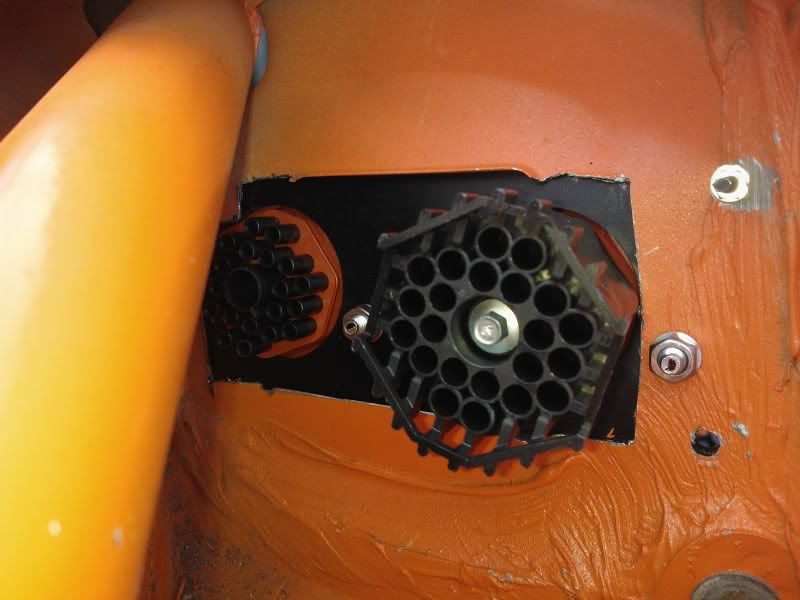

I cut some edge trim for where the wire loom might rub on the body, this was donated very kindly by Daveyboy.

I then got the tank and pump for the water/methanol kit wired in

wire striped and terminal on

then the connector on

I melt the end of the braid to stop it fraying when threading the wire

the loom for this is now complete, but as it started raining I did not get a chance to get take photos of the finished article but will next time i am out there.

chris with a pug

chris with a pug

.

.