Post #10

This is what he had to say regarding my results if it helps anyone

Hi Chris, I will seek to expand on my comments regarding your dyno test.

Detonation/Knock - Abnormal or uncontrolled combustion, from multiple flame fronts causing rapid cylinder pressure and heat rise, beyond design limits , thus causing pistons, rods and bearings to resonate.

Knock can have different intensities ranging from light knock ( on a tip in for example) to destructive knock, which can punch a hole in the piston or break ring lands etc.

Anything that can promote heat in combustion chamber and lead to knock i.e. hot intake air charge, lean running, over advanced spark timing, hot spots, pre ignition etc.

In an engine, for a given air density, fuel octane, compression ratio, engine speed, load and AFR, there is a spark advance that would result in maximum torque or MBT. MBT can be limited by the knock limit overwise know as the boarderline det limit (BLD).

In automotive calibration strategy, when the frequency associated with knock is detected by the knock sensors, action is carried out by the ignition feature to reduce timing to stop the knock. The engine controller can determine which cylinders are knocking due the syncing of the crank signal and the cam phase sensor and stereo knock sensors This is a knock window in crankshaft degress. Spark retard intervention will continue until the knock frequency reduces under a threshold. With knock present, the spark reduction starts from minimum retard setpoint action, incremented to a maximum as the knock persists. If the knock stops, this retard is ramped out to base or MBT timing.

With the requirement to run 3 way catalysts and maximum fuel economy, many engines run at lambda 1 at engine speeds up to 4500rpm. Base timing is usually developed on a nominal fuel octane to deliver MBT under these conditions, both for stead state and in transients. In real life the engine can frequently operated out of this test environment and you will need knock control to stop knock tending towards destruction of the engine.

For your car on the day, there was audible det present when the vehicle was being reversed up the rolls during low engine speeds and light to mid throttle excursions or "tip in". This type of knock is usually not dangerous as the knock feature will just simply compensate as I described above. This suggested to me, during those conditions, the base calibration has been done aggressively Peugeot, allowing the engine to be on the det limit (BLD) and causing the knock system be more active to pull spark out. There is also the possibility the fuel quality was poor and not up to the advertised octane content (less than 95RON).

Now I heard the det when I was entering your details in the machine and the car was driven up the rolls besides me. A bit unusual for the sample of vehicles that were tested there that day, given the ambient temp and the light loads required to reverse the car into the rollers. For OEM work for, we do not calibrate our spark cal to knock at such low engine speeds and light to mid throttle openings. Not even in hot climate testing of ambients of over 40 deg C. Peugeot engineers obviously have a different method and for everyday use I do not see a problem. If I were to calibrate this, pending fuel octane content, I just would calibrate this condition differently.

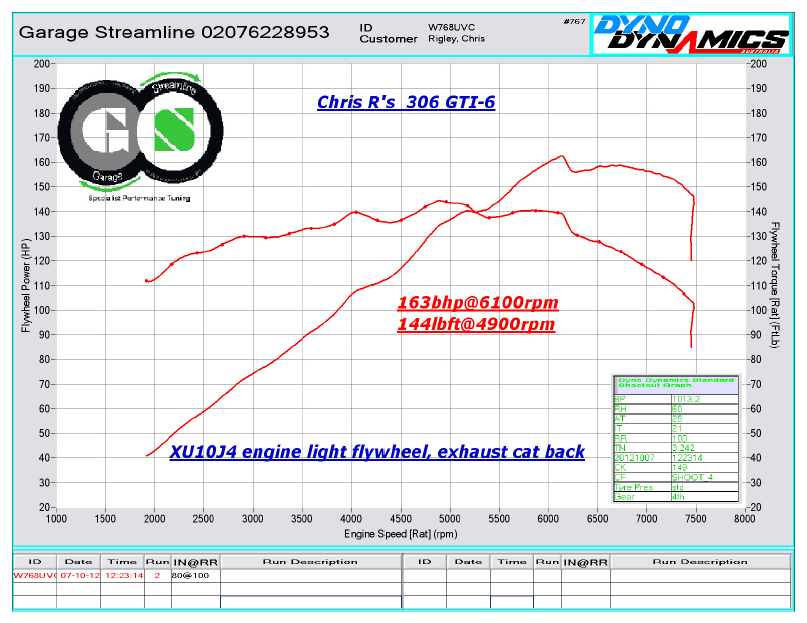

When I was driving the car for the test i.e at full load, I could not hear any audible knock over the external dyno noises at say 3-7000rpm, window down, without my det cans attached to the engine. As a result I do not know if the factory spark settings and perhaps iif the knock system contributed to the torque profile uneveness and perhaps the step in torque at 6200rpm.

Overfueling - Fuel control significantly richer than best torque AFR.

On many factory vehicles, advertised fuel economy/CO2 is very important as is maximum power to an OEM. As indicated above the engine is controlled to achieve a fuel mixture of lambda 1 or more accurately lambda 0.95 to 1.05 for efficient catalyst operation and in turn reducing fuel flow to deliver good drive and FE. At higher loads and engine speeds, the use of lambda 1 may cause excessive heat build up in components, such as the exhaust valves, exhaust pipes and studs. In addition the higher EGTs from lean running can cause the catalyst to exotherm to a brick temperature that could compromise is cell structure (meltdown) and usefulness.

Lambda 1 is also not the best AFR for maximum torque either.

Depending on the depth of calibration strategy, some OEs run a full load fuel set point, richer than LBT (leanest best torque) that achieves cooling of the components. Sometimes the level of fuel set point can cause some cars to run as rich as 11:1, which in turn can reduce maximum torque. This is very common when OE Golf MK3 16v or VR6 was tested at WOT and the fuel mixture, drops to 11:1 from 4500rpm, reducing torque. This fuel set is usually triggered by a load and engine speed threshold. For a NASP petrol engine I can achieve maximum torque at ~ 12.4-13.1 AFR targets.

Your mixture plot for WOT, was significant richer than the above and in places as low as 11:1 AFR. Apart from the step at 6200rpm, the change in fuel mixture also seemed to affect the torque plot.

You should understand I am only describing what I have witnessed at WOT and the effects on maximum measured power and torque on the day. I would expect part load operation would run at lambda 1 and not cause a concern for fuel economy.

Regarding remapping.

I am an OEM professional and have many responsibilities in my role at Ford, some overseas. If I had bin file, addresses of parameters, and logic book for your vehicle's PCM, I would be happy to deliver a more robust calibration that addresses what I described above, leading to more torque and as a possibly power. However without a collection of these, it maybe time consuming and becomes a second job to source. I beleve if this ECU carries an EPROM, I already have buring tools and EEPROM. I am happy to tweak vehicles that are well known, such as older Golfs, JDM stuff etc, in my spare time on a hobby basis i.e. like Simon's.

The advise that was given, was independent and can be used by someone who has these files and equipment to make targeted changes to the vehicle cal, leading to an improvement if it was tested in a back to back or if you were to revisit the Garage Streamline dyno in the future.

________________________________________

''Oh, it does handle like a golf!'' Why drive a Golf....when you can drive a GTi-6?

The Coolest

The Coolest