Step 1. Get the aircraft finishers at work to bead blast the front faces of the beauties

Good to see that MoD employees using MoD equipment in no doubt MoD time still charge - this practice is called a 'rabbit'.

Same MoD guy gave me loads of differing grades of pads for my vibrating tool so I went to work for a loooong time on them

Then it was time for somewhere to paint them. Hmmm in my nice little tool store at work is ideal, seeing as that's where I've done all the other stuff!

Sadly didn't get too many of them as was busy wearing gloves and a white paper suit but here they are afterwards. In between all coats of primer and paint there was a gentle rub(!) of 1200 grit

So, what to do next...I need somewhere for them out the way for the lacquer to harden...

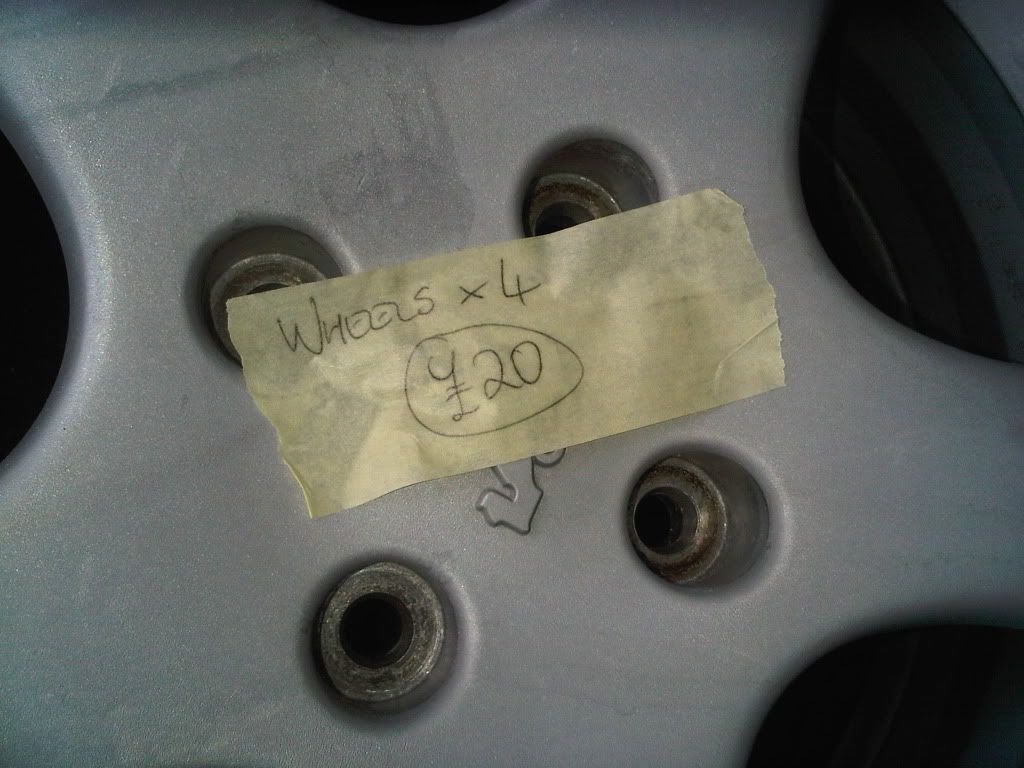

But wait, what's this?

An office heater? Surely not! Hmmm 3 days at Gas Mk 4 should do it

Et voila...serve piping hot

That place is where I do all my servicing too...

gilesy

gilesy